Shaker cabinets have dominated kitchen design for over two centuries—not through trendy marketing, but through proven durability and timeless aesthetics. Originally crafted by the Shaker religious community in the 18th century, these cabinets emphasized utility, quality craftsmanship, and honest materials. Today, selecting the right materials for Shaker cabinets requires understanding how wood species, engineered substrates, joinery methods, and finishing systems work together to create installations that withstand decades of daily use.

The durability difference is dramatic: A properly specified Shaker cabinet using quality materials can deliver 30+ years of service life, while poorly constructed alternatives may fail within 5-10 years. For contractors and designers specifying cabinetry for clients, material selection determines approximately 80% of long-term performance.

This guide examines the critical material decisions that separate budget builds from investment-grade cabinetry, with special attention to Fabuwood’s industry-leading durability specifications and construction standards.

Key Takeaways: Material Selection Principles

For Contractors and Designers

- Material selection determines 80% of cabinet longevity. Construction quality, hardware, and finish account for the remaining 20%.

- Plywood is non-negotiable for sink bases regardless of overall project budget tier. The cost differential is minor compared to replacement expenses when particleboard fails.

- Hybrid door construction (solid wood frames + MDF panels) represents best-practice engineering for painted Shaker cabinets, not cost-cutting.

- Dovetail drawer joinery outlasts alternatives by 5-10x. The labor premium is justified by dramatically extended service life.

- Hardware quality compounds benefits over decades. Blum’s 200,000-cycle testing versus 25,000-cycle KCMA minimum translates to 25+ years of reliable operation.

- 2K polyurethane finish prevents the joint cracking that plagues painted Shaker cabinets with traditional finishes. Flexibility to bridge wood movement is essential.

- Total cost of ownership favors premium materials over 30-year timeframes. Budget cabinets requiring replacement every 12 years accumulate higher costs than premium cabinets requiring only refinishing.

- Fabuwood’s dual AWI Premium + KCMA certifications provide documentation that satisfies architectural specifications while maintaining semi-custom pricing and 2-4 week lead times.

- Moisture management matters as much as material quality. Even premium materials fail prematurely when exposed to sustained moisture or extreme humidity fluctuations.

- Client education prevents warranty disputes. Seasonal door gaps, wood movement, and painted stress lines at joints are normal material behavior, not quality defects.

Understanding Shaker Cabinet Construction Systems

Shaker cabinets consist of three primary structural systems, each requiring specific material considerations:

1. The Cabinet Door

- Frame-and-panel construction: Vertical stiles, horizontal rails, and recessed center panel

- Standard dimensions: 3/4″ door thickness, 2-1/4″ to 3″ stile/rail width

- Critical junction: The rail-and-stile joint creates a horizontal ledge that traps liquids—a key vulnerability point

2. The Cabinet Box (Carcass)

- Structural enclosure: Holds shelves, supports countertops, anchors installation

- Load requirements: Must support 15-20 lbs/sq ft for granite/quartz countertops

- Moisture exposure: Base cabinets face the harshest conditions

3. The Drawer System

- Components: Drawer box, slides, and front panel

- Mechanical stress: Endures thousands of load/unload cycles annually

- Weight capacity: Quality drawers support 75-100 pounds

Key takeaway: Material performance requirements differ dramatically between these systems. Optimal specifications match each material to its specific structural demands.

Wood Species Selection: Hardness, Grain, and Performance

The Janka hardness scale measures wood’s resistance to denting and wear by measuring the force (in pounds) required to embed a 0.444-inch steel ball halfway into the wood. For Shaker cabinets serving busy kitchens, hardness directly correlates with long-term appearance retention.

Janka Hardness Rankings for Cabinet Woods

| Wood Species | Janka Rating (lbf) | Stability | Best Use | Cost Tier |

|---|---|---|---|---|

| Hickory | 1,820 | Medium | High-impact areas, rustic designs | $$$ |

| Hard Maple | 1,450 | High | Painted cabinets, high-traffic kitchens | $$ |

| White Oak | 1,360 | High | Stained finishes, wet areas | $$$ |

| Red Oak | 1,290 | Medium | Traditional designs, general use | $$ |

| Walnut | 1,010 | High | Luxury stained cabinets | $$$$ |

| Cherry | 950 | High | Transitional/traditional, develops patina | $$$ |

| Birch | 910 | High | Painted budget-friendly option | $ |

| Alder | 590 | Medium | Uniform staining, low-traffic areas | $ |

Professional Species Selection Guide

Hard Maple (1,450 lbf)

- Ideal for: Painted Shaker cabinets, high-traffic kitchens

- Why it works: Fine, closed grain creates glass-smooth painted surfaces with minimal grain telegraphing

- Durability factor: Superior dent resistance prevents the surface damage that plagues softer woods

- Cost: ~$27/sq ft for cabinet doors

- Watch out for: Can exhibit blotchy stain absorption without wood conditioner

White Oak (1,360 lbf)

- Ideal for: Stained finishes, base cabinets near sinks

- Why it works: Natural tyloses (cellular membranes) block pores, creating inherent water resistance

- Durability factor: Closed-grain structure provides superior moisture protection versus red oak

- Best application: Sink bases, dishwasher surrounds, bathroom vanities

- Visual characteristic: Bold, traditional grain patterns

Cherry (950 lbf)

- Ideal for: Traditional/transitional designs, medium-traffic areas

- Why it works: Fine grain with rich tones that deepen naturally over time

- Durability factor: Adequate hardness for residential use; develops attractive patina with age

- Important note: UV exposure causes natural darkening—educate clients on this characteristic

- Price premium: Reflects aesthetic qualities and limited availability

Hickory (1,820 lbf)

- Ideal for: Maximum impact resistance, rustic/farmhouse designs

- Why it works: Hardest domestic hardwood—virtually impervious to dents

- Durability factor: Dramatic color variation (cream to dark brown) hides wear patterns

- Trade-off: High shrinkage coefficients cause movement with humidity changes

- Cost: ~$30/sq ft

Birch (910 lbf)

- Ideal for: Budget-conscious painted cabinets

- Why it works: Fine grain accepts paint beautifully; most warp-resistant cabinet wood

- Durability factor: Adequate hardness for most residential applications

- Cost advantage: ~$24/sq ft for paint-grade doors

- Limitation: Variable porosity makes even staining difficult

Engineered Substrates: When Technology Outperforms Nature

Engineered wood products combine wood fibers or veneers with adhesives to create panels with specific performance characteristics. For certain applications, these materials outperform solid wood in dimensional stability, moisture resistance, and cost-effectiveness.

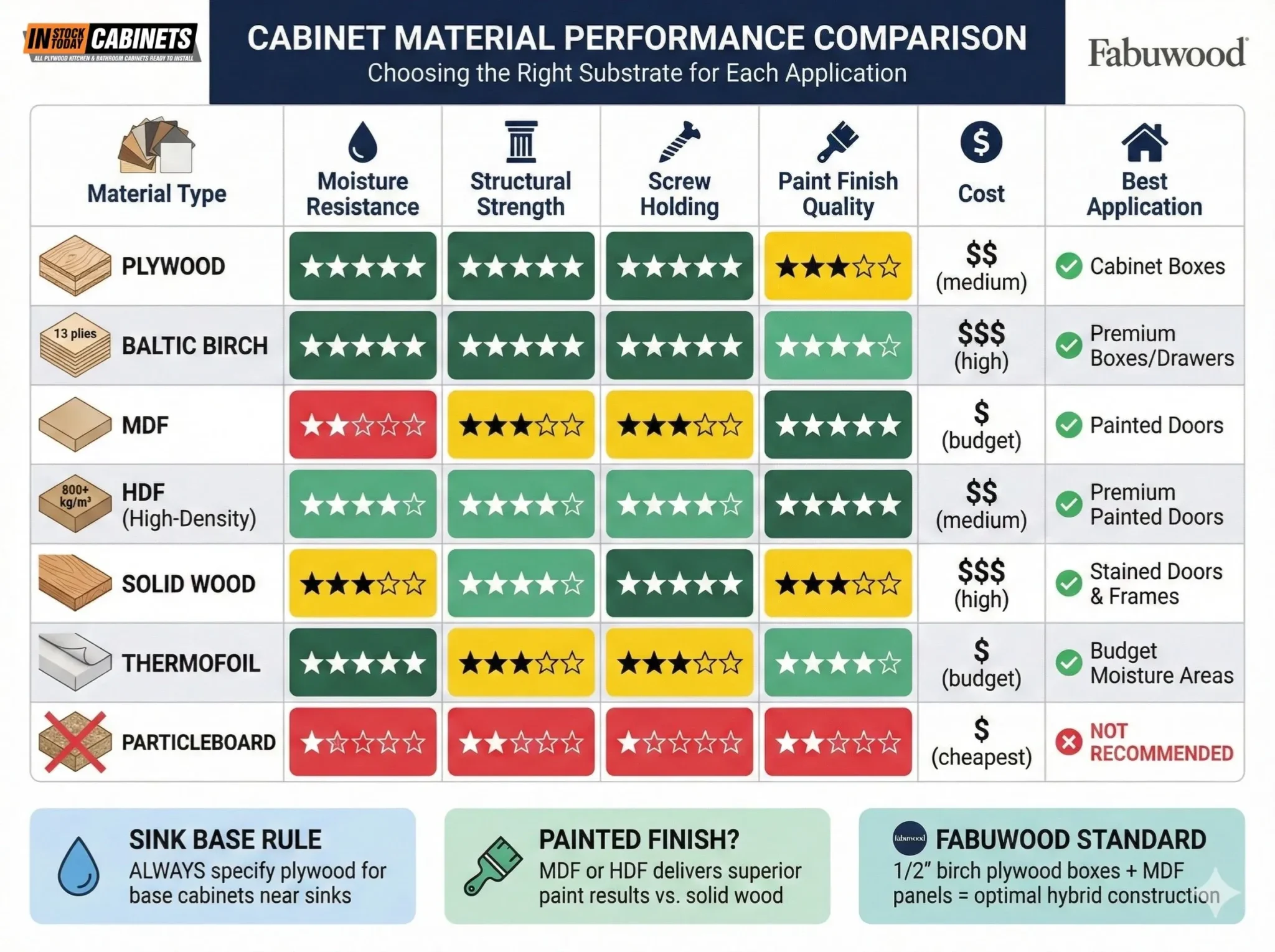

Material Performance Comparison Matrix

| Material | Moisture Resistance | Structural Strength | Screw Holding | Paint Finish Quality | Cost Index | Best Application |

|---|---|---|---|---|---|---|

| Plywood | ★★★★★ | ★★★★★ | ★★★★★ | ★★★☆☆ | 1.5× | Cabinet boxes |

| Baltic Birch | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | 2.0× | Premium boxes / drawers |

| MDF | ★★☆☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ | 1.0× | Painted doors |

| HDF | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★★ | 1.2× | Painted doors / panels |

| Solid Wood | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | 1.8× | Doors & frames |

| Thermofoil | ★★★★★ | ★★★☆☆ | ★★★☆☆ | ★★★★☆ | 1.0× | Budget doors |

| Particleboard | ★☆☆☆☆ | ★★☆☆☆ | ★☆☆☆☆ | ★★☆☆☆ | 0.8× | Not recommended |

Plywood for Cabinet Boxes: The Professional Standard

Why plywood dominates quality construction:

- Cross-grain lamination: Alternating veneer directions create equal strength in both axes

- Moisture resilience: Layered construction prevents deep moisture penetration

- Screw holding: Veneer layers provide superior fastener retention versus particleboard

- Load capacity: Resists sagging under heavy countertop loads (15-20 lbs/sq ft)

Critical specifications:

- Thickness: 3/4″ for sides, tops, bottoms, and shelves

- Back panels: Minimum 1/2″ plywood (3/4″ for premium installations)

- Veneer quality: Face veneers should measure 1/32″ to 1/38″ thick

- Ply count: 7-9 layers minimum in 3/4″ material

Moisture performance: Plywood withstands intermittent wetting without catastrophic swelling. Unlike particleboard, which swells permanently when wet, plywood maintains structural integrity even when damp—essential for sink bases and dishwasher surrounds.

Baltic Birch: The Premium Upgrade

What makes Baltic Birch exceptional:

- All-birch construction: 100% birch veneers with no softwood filler

- Void-free: No gaps between plies—every screw bites solid wood

- Ply count: 11-13 layers in 3/4″ material versus 7-9 in standard plywood

- Clean edges: Dense lamination creates exhibition-quality edges

Applications justifying premium cost:

- Wide frameless cabinets requiring maximum rigidity

- Dovetail drawer construction demanding superior screw holding

- Exposed edges where edge-banding isn’t desired

- Floating vanities under tensile stress

Specification note: Baltic Birch uses metric sizing (18mm vs. 3/4″)—account for this in dado and groove dimensions.

MDF and HDF for Painted Surfaces

Why engineered fiberboard outperforms solid wood for paint:

Modern cabinet manufacturers—including Fabuwood—use MDF or HDF for center panels in painted Shaker doors. This isn’t cost-cutting; it’s engineering.

Technical advantages:

- Zero grain structure: No wood grain telegraphs through paint over time

- Isotropic properties: Uniform expansion in all directions (solid wood expands perpendicular to grain)

- Crack prevention: Eliminates the hairline cracks that appear at solid wood rail-stile joints

- Surface perfection: Creates glass-smooth substrates for high-gloss finishes

Density comparison:

- Standard MDF: 600-750 kg/m³ (suitable for protected applications)

- HDF: 800+ kg/m³ (superior moisture resistance and edge quality)

- MR-MDF: Moisture-resistant grade with MDI resins (green-tinted core)

Moisture limitations: Standard MDF swells irreversibly when wet. For bathroom vanities and near-sink applications, specify:

- MR-MDF (moisture-resistant formulation)

- HDF (higher density provides inherent moisture protection)

- Sealed edges with primer and paint on all cut surfaces

The hybrid door advantage: Premium manufacturers combine solid hardwood frames (structural rigidity, hinge-mounting strength) with HDF center panels (dimensional stability, perfect paint substrate). This construction delivers the best properties of both materials.

Fabuwood’s Durability Specifications: Industry-Leading Standards

Fabuwood has earned recognition as a leading semi-custom manufacturer by achieving rare AWI Premium Grade certification—the highest level of architectural woodwork certification. This distinction, combined with KCMA certification, provides documented proof of construction quality that exceeds industry minimums.

Dual Certification: What It Means

AWI Premium Grade Certification (Achieved September 2023)

- Significance: Top tier of the Architectural Woodwork Institute’s three-level system (Economy < Custom < Premium)

- Testing validation: Joints, frames, doors, and shelves meet demanding architectural specifications

- Load capacity: Tall pantry cabinets tested to support 2,250 pounds

- Industry context: Few semi-custom manufacturers achieve Premium grade

KCMA A161.1 Certification

- Shelf testing: Must withstand 15 lbs/sq ft for seven consecutive days

- Drawer cycling: Survives 25,000 open-close cycles under load

- Finish durability: 24-hour exposure to vinegar, citrus, ketchup, coffee, olive oil, 100-proof alcohol

- Heat resistance: 120°F at 70% humidity for 24 hours

Fabuwood Construction Specifications

Cabinet Box Construction:

- Material: 1/2″ select birch plywood for sides, tops, bottoms

- Back panels: 1/2″ solid plywood backs (not 1/4″ thin panels)

- Face frames: 3/4″ solid birch with mortise-and-tenon joinery

- Shelves: 3/4″ edge-banded plywood

Door Construction (Allure Series):

- Frame: 3/4″ solid birch rails and stiles

- Center panel: 3/8″ MDF with captured-panel technique

- Engineering benefit: MDF panel prevents cracking during humidity swings while birch frame provides hinge stability

Drawer Construction:

- Sides: 5/8″ solid birch with dovetail joinery

- Bottoms: 3/8″ plywood (not stapled particle board)

- Joinery: Full dovetail construction—typically reserved for higher price points

Hardware Package:

- Hinges: Blum Compact Clip concealed hinges (model #39C355B.20)

- Soft-close: Integrated Blumotion technology (no add-on dampeners)

- Cycle testing: Blum hinges tested to 200,000 cycles (8x KCMA minimum)

- Adjustability: Six-way adjustment, 110-degree opening

- Drawer slides: Blum Tandem plus Blumotion full-extension

- Weight capacity: 90-125 pounds per pair

Fabuwood Product Tiers

| Series | Door Material | Box Material | Hardware | Price Point | Best For |

|---|---|---|---|---|---|

| Allure | Solid birch frame + MDF panel | 1/2″ birch plywood | Blum soft-close | Mid-range | Owner-occupied homes |

| Nexus | Solid wood / MDF hybrid | Plywood | Blum | Mid-range | Contemporary designs |

| Galaxy | Painted solid / MDF | Plywood | Blum | Mid-range | High-traffic kitchens |

| Illume | Frameless, HDF doors | Plywood | Blum | Upper mid-range | Modern European style |

95% of Fabuwood sales: Allure series variations—demonstrating market preference for solid construction at competitive pricing.

Competitive Advantage Analysis

How Fabuwood delivers premium features at mid-range pricing:

- Efficient manufacturing: Newark, NJ facility with streamlined assembly processes

- Volume purchasing: Bulk Blum hardware procurement reduces per-unit costs

- Standard options: Limited customization compared to full custom (but comprehensive for 90% of projects)

- Lead time efficiency: 2-4 weeks standard (5-7 days expedited) vs. 6-8+ weeks for competitors

Warranty coverage: Limited lifetime warranty for original purchaser—significant compared to 5-10 year competitors.

Construction Methods: Joinery That Lasts Decades

Joinery methods determine how well cabinets withstand mechanical stress, wood movement, and daily use. The differential between quality and economy joinery becomes apparent within 5-10 years.

Door Joinery: Cope-and-Stick vs. Mitered

Cope-and-Stick (Mortise-and-Tenon) — RECOMMENDED

How it works:

- Rail ends machined with “cope” (negative profile)

- Stiles receive “stick” (positive profile) running full length

- Interlocking profiles create mechanical bond

Durability advantages:

- Increased glue surface: Profile geometry provides 30% more surface area than butt joints

- Self-alignment: Tongue prevents twisting and misalignment

- Expansion accommodation: Rail butts into stile side—vertical expansion doesn’t create visible gaps

- Joint orientation: Vertical joint line hides seasonal movement

Professional specification: For painted Shaker cabinets requiring 20+ year service life, cope-and-stick joinery is the only scientifically defensible choice.

Mitered Construction — USE WITH CAUTION

Why miters fail:

- Both pieces expand perpendicular to grain (at 45° to joint line)

- Humidity increase: Outside points push apart (“points open”)

- Humidity decrease: Inside corners pull apart (“heels open”)

- Result: Hairline cracks in paint within 3-5 years

When miters are necessary:

- Wrapped profiles requiring continuous corner detail

- Required reinforcement: Blind splines, biscuits, or floating tenons (Dominos)

- End-grain glue alone guarantees failure

Drawer Joinery: The Dovetail Advantage

Dovetail Construction — GOLD STANDARD

Mechanical superiority:

- Interlocking pins and tails distribute tensile loads across multiple contact points

- Wedge shape strengthens under pulling forces (opposite of weakening)

- Performance differential: 30% more durability than rabbet joints

- Lifespan multiplier: Outlasts dowel or stapled construction by 5-10x

Dovetail variations:

- English dovetails: Joinery extends to corner edge—maximum strength, most interior space

- French dovetails: Single groove construction—weaker thin edges

- Through dovetails: Visible on drawer face (traditional furniture)

- Half-blind dovetails: Hidden on drawer front (standard cabinet construction)

Material specifications for dovetail drawers:

- Sides: 5/8″ solid hardwood (maple most common)

- Bottoms: 3/8″-1/2″ plywood set into dados

- Critical detail: Bottom captured in grooves, not stapled—distributes weight across perimeter

Mid-Range Alternative: Dowel Joints

- Reduces labor costs versus dovetails

- Maintains solid wood sides and dadoed bottoms

- Adequate durability for moderate-use applications

AVOID: Stapled/Butt Joints

- Frequently fail within 10-15 years under normal use

- Concentrated stress on fasteners rather than distributed mechanical bonds

- Not acceptable for quality installations

Cabinet Box Assembly Methods

Face-Frame Construction (American Standard)

- Method: 3/4″ x 1-1/2″ solid hardwood frame attached to box front

- Advantages: Prevents racking, stable hinge mounting, 2-1/2″ cabinet-to-cabinet screws

- Market share: 55-60% of US cabinet market

- Durability: Proven over centuries of use

Frameless Construction (European Style)

- Method: Panels provide structural support without face frame

- Advantages: 15-20% more interior access (15″ cabinet = 12″ drawer opening vs. 10.25″)

- Requirements: Thicker panels (3/4″ minimum), precise manufacturing tolerances

- Market share: 73% of global cabinet market

- Critical consideration: Material quality even more important—panels must provide structural integrity

Back Panel Integration:

- Captured backs: Set into dado grooves on all four sides—maximum racking resistance

- Applied backs: Stapled to rear—budget construction, adequate for light-duty only

- Professional spec: Captured backs for cabinets supporting significant weight or spanning long runs

Finish Chemistry: Protection That Performs

The finish system is your primary defense against chemical attack, moisture infiltration, and physical abrasion. In professional cabinetry, there’s a paradigm shift occurring from traditional varnishes to advanced urethane systems.

Finish Performance Comparison

| Finish Type | Solids Content | Hardness | Flexibility | Water Resistance | Chemical Resistance | Yellowing | Lifespan |

|---|---|---|---|---|---|---|---|

| Pre-Cat Lacquer | 15–25% | Low | Low | Low (blushes) | Low | High | 5–10 years |

| Conversion Varnish | 40–50% | Very High | Low | High | High | Moderate | 15–20 years |

| 2K Polyurethane | 45–60% | High | High | Very High | Very High | Low | 20–30+ years |

Conversion Varnish (CV): The Professional Standard

Chemistry: Acid-catalyzed cross-linking resin

Performance advantages:

- Exceptionally hard film with excellent chemical resistance

- High solids content builds protective thickness efficiently

- Cures to 85% in 48 hours, 95% in 10 days

- Withstands acetone, nail polish remover, 100-proof alcohol

Critical limitation: Brittleness

- Low elongation (flexibility)

- Cannot stretch when wood substrate moves

- Micro-cracks at joints allow moisture entry

- Result: Accelerated failure at stress points

Safety note: Off-gasses formaldehyde during curing

2K Polyurethane: The New Professional Standard

Chemistry: Polyol resin + isocyanate hardener = urethane polymer

Why 2K poly is superior for Shaker cabinets:

- Elasticity: High tensile elongation allows finish to “bridge” wood movement without cracking

- Joint protection: For painted Shaker doors, this is the single most effective defense against rail-stile joint cracking

- Chemical resistance: Superior to CV against solvents and acids

- Moisture sealing: Effectively seals the “Shaker ledge” against standing water

- UV stability: Acrylic-based formulas are non-yellowing—whites stay white indefinitely

Application requirements:

- Professional spray booth with proper ventilation required

- Fresh-air respirators mandatory (isocyanates are respiratory sensitizers)

- Mixed product hardens in pot within hours—requires disciplined workflow

- Not DIY-friendly

KCMA Finish Testing Standards:

- 24-hour exposure: vinegar, citrus, ketchup, coffee, olive oil, 100-proof alcohol

- 1-hour mustard exposure

- Thermal cycling: 120°F to -5°F

- Heat/humidity test: 120°F at 70% humidity for 24 hours

Fabuwood applies conversion varnish across product lines, explaining superior finish durability noted in professional reviews. Conversion varnish meets demanding KCMA standards while providing cost-effective professional finishing.

Painted vs. Stained: Durability Considerations

Painted Finish Advantages:

- Uniform color across mixed materials (wood + MDF)

- Refinishing capability (can change colors)

- Moisture barrier (when properly applied)

- Light colors (white, cream, gray) hide wear better than dark colors

Painted Finish Challenges:

- Chipping reveals contrasting substrate

- Touch-ups rarely match perfectly

- Joint cracking at stress points (mitigated with 2K poly)

- Requires 4-6 mil dry film thickness for durability

Stained Finish Advantages:

- Scratches less visually apparent (damage shows grain, not contrast)

- Touch-ups blend more successfully

- Develops attractive patina over time

- Natural material showcases investment in quality wood

Stained Finish Challenges:

- Gradual fading from UV exposure (5-7 years on south-facing cabinets)

- Requires periodic resealing (every 5-10 years)

- Limited color change options without complete refinishing

- Grain telegraphing on open-pore woods

Hardware: The Mechanical Components That Matter

Hardware quality affects daily functionality and determines whether cabinets remain tight and aligned after decades of use.

Hinge Specifications: Load Capacity and Cycle Life

Premium tier: Blum (used by Fabuwood)

- Cycle testing: 200,000 open-close cycles

- Lifespan translation: 25+ years with heavy daily use (20 cycles/day)

- Component count: CLIP top BLUMOTION contains 32-58 individual components

- Adjustment: Six-way adjustment capability

- Opening: 110-degree standard (120-degree wide-angle available)

Mid-tier: Hettich, Grass, Salice

- Cycle testing: 80,000-150,000 cycles

- Adequate for: Most residential applications

- Cost: 20-40% below Blum

Economy tier: Generic brands

- Cycle testing: 25,000-50,000 cycles (KCMA minimum is 25,000)

- Lifespan: 5-10 years in active kitchens

- Failure mode: Loosening, sag, spring weakness

Hinge Count: The Rule of Three

| Door Height | Required Hinges | Max Weight (Standard) | Max Weight (Heavy Duty) |

|---|---|---|---|

| Up to 36″ | 2 hinges | 25 lbs | 45 lbs |

| 36″ – 60″ | 3 hinges | 40 lbs | 75 lbs |

| 60″ – 80″ | 4 hinges | 55 lbs | 95 lbs |

| 80″ – 95″ | 5 hinges | 70 lbs | 115 lbs |

Why the third hinge matters:

- Acts as fulcrum, reducing moment arm on top hinge

- Prevents sag on tall doors (especially heavy HDF/solid wood)

- Distributes stress across three mounting points rather than two

- Professional specification for any door exceeding 40″ height

Drawer Slide Performance Specifications

Undermount Full-Extension with Soft-Close — RECOMMENDED

Advantages:

- Protection: Slides hidden from dust and debris

- Capacity: Maximizes usable drawer width (no side-mount hardware intrusion)

- Shock absorption: Soft-close prevents joint-loosening impacts

- Smooth operation: Ball-bearing mechanisms for decades of smooth function

Blum TANDEM plus BLUMOTION specifications:

- Component count: 170 individual components

- Cycle rating: 100,000 cycles

- Weight capacity: 90 lbs standard, 125 lbs heavy-duty

- Extension: 100% full extension for complete drawer access

Critical specification for wide drawers:

- Drawers exceeding 24″ width require stabilizer kits

- Prevents racking (out-of-square distortion)

- Maintains parallel drawer operation over lifespan

Heavy-duty alternative: Grass Dynapro

- Dynamic rating: 40kg (88 lbs)

- Static capacity: 100kg (220 lbs)

- Application: Oversized pot-and-pan drawers, dense item storage

Handles and Pulls: Material Durability

| Material | Durability Rating | Corrosion Resistance | Cost | Best Application |

|---|---|---|---|---|

| Solid Brass | 9/10 | High | $$$ | Traditional / transitional |

| Stainless Steel 316 | 10/10 | Very High | $$$$ | Modern / contemporary |

| Stainless Steel 304 | 9/10 | High | $$$ | General residential |

| Zinc Alloy | 8/10 | Moderate | $$ | Budget projects |

| Plated Materials | 6/10 | Low | $ | Avoid in humid environments |

Shaker cabinet handle placement standards:

- Base cabinets: 2-3″ from upper corners

- Wall cabinets: 2-3″ from lower corners

- Centered on stiles: Proper visual proportion

- Drawer pulls: Centered horizontally and vertically

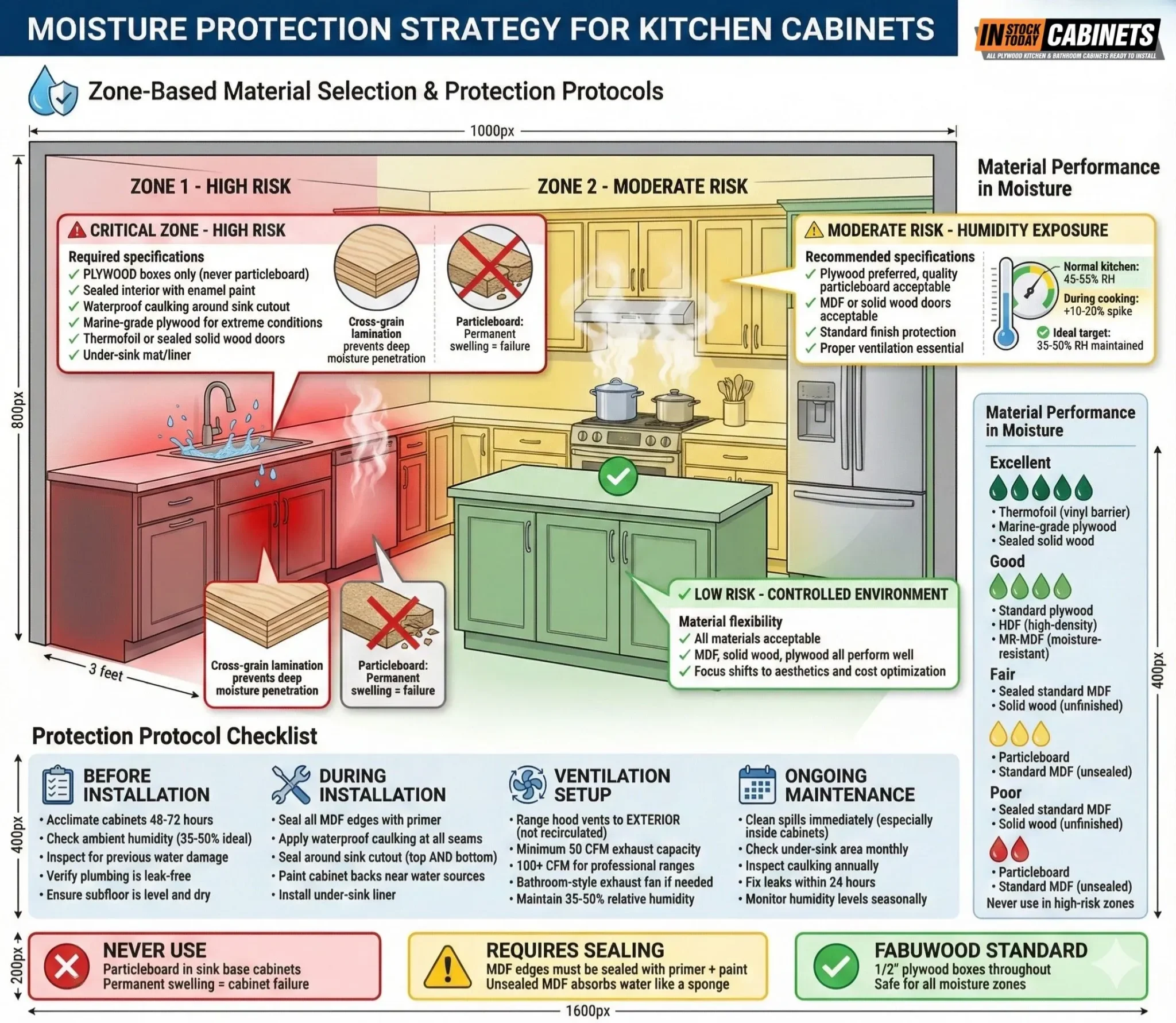

Moisture Management: Engineering Longevity

Kitchen cabinets face continuous exposure to humidity, temperature fluctuations, and direct water contact. Effective moisture management extends cabinet life from 10-15 years to 25-30+ years.

Critical Moisture Protection Strategies

1. Material Selection by Zone

High-risk zones (within 3 feet of sinks/dishwashers):

- ✅ Cabinet boxes: Plywood only (never particleboard)

- ✅ Doors: Solid wood, thermofoil, or properly sealed MDF

- ✅ Interior finish: Heavy enamel paint sealing all surfaces

- ✅ Back panels: 1/2″-3/4″ plywood (not thin hardboard)

Moderate-risk zones (general kitchen):

- ✅ Cabinet boxes: Plywood preferred, quality particleboard acceptable

- ✅ Doors: All materials acceptable

- ✅ Consideration: Humidity during cooking (10-20% above ambient)

Low-risk zones (islands, upper cabinets away from water sources):

- ✅ Material flexibility: MDF, solid wood, engineered products all perform well

- ✅ Focus shifts: Aesthetics and cost optimization

2. Sealing and Caulking Protocol

Waterproof caulking required at:

- Cabinet-to-wall junctions

- Cabinet-to-floor junctions (base cabinets)

- Cabinet-to-countertop junctions

- Around all plumbing penetrations

- Sink cutouts (both top and bottom surfaces)

Additional sealing:

- Cabinet backs near sinks: water-resistant finish before installation

- Under-sink cabinet interiors: heavy enamel paint

- All MDF edges: primer and paint before assembly

3. Ventilation Management

Kitchen ventilation minimums:

- Range hood: Exterior venting (not recirculating)

- CFM capacity: Minimum 50 CFM per building code, 100+ CFM for professional ranges

- Target humidity: Maintain 35-50% relative humidity

- Humidity spikes: Normal during cooking; ventilation manages recovery time

Signs of inadequate ventilation:

- Condensation on cabinet doors near range

- Grease film accumulation accelerating

- Warping or swelling of door panels

- Finish failure near heat/moisture sources

4. Wood Movement Management

Understanding hygroscopic expansion:

- Wood swells 3-5% in high humidity (primarily across grain)

- Seasonal door gaps are normal behavior, not defects

- Quarter-sawn lumber expands in thickness, not width—reduces stress on joints

- MDF center panels eliminate large-scale expansion in door centers

Client education critical:

- Seasonal 1/16″-1/8″ gap variations are normal

- One complete heating/cooling season required for full acclimation

- Apparent warping often self-corrects as materials equilibrate

5. Cabinet Acclimation Protocol

Before installation:

- 48-72 hours in installation space

- Allows wood moisture content to equilibrate with ambient conditions

- Prevents immediate expansion/contraction causing misalignment

- Especially critical: climate-controlled warehouse → humid basement transition

Environmental Considerations and Compliance

Durability cannot come at the cost of indoor air quality or environmental responsibility.

Formaldehyde Emission Standards

CARB Phase 2 / TSCA Title VI Limits:

- Hardwood plywood: Maximum 0.05 ppm formaldehyde

- MDF: Maximum 0.11 ppm formaldehyde

- Compliance: Mandatory for all composite wood products

- Verification: Manufacturers must provide compliance documentation

NAF (No Added Formaldehyde) Options:

- Adhesive types: Soy-based or pMDI (polymeric methylene diphenyl diisocyanate)

- Performance benefit: Often indicates higher-quality, more moisture-resistant resin

- Air quality: Eliminates formaldehyde emissions entirely

- Premium positioning: NAF materials command 10-15% price premium

Why this matters for contractors:

- California requirements apply to products sold nationwide (federal TSCA Title VI mirrors CARB)

- Non-compliant materials create liability

- Clients increasingly request low-VOC/NAF materials

- Green building certifications (LEED) require compliance documentation

Sustainable Sourcing

FSC Certification (Forest Stewardship Council):

- Ensures wood from responsibly managed forests

- Particularly relevant for high-demand species (White Oak)

- Chain-of-custody documentation verifies sourcing

- May be required for LEED certification

Cost Analysis and Budget Optimization

Understanding cost drivers enables specification optimization without sacrificing critical quality elements.

Price Tiers and Expected Lifespan

| Quality Tier | Cost Range (per linear foot) | Box Material | Door Material | Hardware | Expected Lifespan | Total Kitchen Cost (10×10) |

|---|---|---|---|---|---|---|

| Budget | $100–$150 | Particleboard | Thermofoil / laminate | Basic | 10–15 years | $1,200–$4,400 |

| Mid-Range | $150–$650 | Plywood | MDF (painted) or solid wood | Soft-close | 15–25 years | $4,400–$18,000 |

| Premium | $500–$1,200+ | Baltic Birch | Solid hardwood | Premium soft-close | 30–50+ years | $18,000–$35,000+ |

Fabuwood positioning: Upper mid-range pricing ($400-650/linear foot) with premium construction features (AWI Premium certification, all-plywood boxes, Blum hardware, dovetail drawers).

Total Cost of Ownership Analysis (30-Year Timeframe)

Budget tier (12-year replacement cycle):

- Initial: $4,000

- Replacement #1 (year 12): $4,500 (inflation)

- Replacement #2 (year 24): $5,000

- Total: $13,500

Mid-range tier (20-year replacement cycle):

- Initial: $10,000

- Replacement (year 20): $12,000

- Total: $22,000

Premium tier (refinish at year 20):

- Initial: $22,000

- Refinishing (year 20): $3,000

- Total: $25,000

Key insight: Premium cabinets cost just 14% more over 30 years while delivering 2-3x the service life and maintaining higher resale value.

Material Cost Breakdown (2026 Pricing)

Shaker cabinet door costs per square foot:

- Paint-grade MDF: $24 (minimum $35/piece)

- Maple (painted): $27 (minimum $40/piece)

- Alder (stained): $28 (minimum $41/piece)

- Hickory (stained): $30 (minimum $45/piece)

- Cherry (stained): $32 (minimum $48/piece)

- Walnut (stained): $38+ (minimum $55/piece)

Finish application costs:

- Clear lacquer: +$14/sq ft

- Stain and lacquer: +$20/sq ft

- Painted finish: +$29/sq ft

- Custom finishes: +$41+/sq ft

Note: Finish costs often equal or exceed base material costs, making finish selection a critical budget variable.

Hybrid Construction Cost Optimization

Strategy: Specify premium materials where performance matters, optimize where it doesn’t.

Recommended hybrid approach:

- Cabinet boxes: Plywood for all applications (non-negotiable for durability)

- Doors: MDF for painted applications (superior finish), solid wood for stained

- Drawer boxes: Dovetail construction (massive longevity benefit for modest cost increase)

- Hardware: Premium soft-close (prevents cumulative damage over decades)

- Finish: 2K polyurethane for painted (prevents crack repairs)

Cost savings: 15-25% compared to all-premium materials while maintaining critical quality elements

Where NOT to compromise:

- Sink base cabinet boxes (must be plywood)

- Drawer joinery (dovetail investment pays off)

- Hardware (cheap hinges/slides fail predictably)

- Back panel thickness (racking resistance)

Material Selection Decision Framework

Selection Matrix by Application

For contractors specifying materials:

High-Moisture Applications (Base Cabinets Near Sinks, Dishwashers)

Cabinet boxes:

- ✅ First choice: Plywood (moisture resilience mandatory)

- ⚠️ Avoid: Particleboard (swells permanently when wet)

- ✅ Premium: Marine-grade plywood in extreme humidity

Doors:

- ✅ First choice: Thermofoil (waterproof vinyl barrier)

- ✅ Second choice: Properly sealed solid wood or HDF

- ⚠️ Third choice: MDF only if MR-grade with sealed edges

Additional protection:

- Heavy enamel interior finish

- Waterproof caulking at all seams

- Under-sink liner/mat for spill protection

Painted Finish Priorities (Contemporary, High-Gloss, Smooth Surfaces)

Doors:

- ✅ First choice: HDF or MDF center panels with solid wood frames (hybrid construction)

- ✅ Second choice: All-MDF doors (budget-conscious)

- ✅ Third choice: Hard maple solid wood (if refinishing capability required)

Why MDF outperforms:

- Zero grain telegraphing through paint

- No joint cracking at rail-stile junctions

- Glass-smooth substrate for high-gloss finishes

- 20-40% cost savings versus solid wood

Finish specification:

- 2K polyurethane (flexibility prevents joint cracks)

- 4-6 mil dry film thickness minimum

- Semi-gloss or high-gloss for maximum durability

Stained Finish Priorities (Traditional, Grain Showcase, Natural Character)

Doors — select species by aesthetic goal:

- Rich, warm tones that darken: Cherry (develops red-brown patina)

- Dramatic grain, traditional: Red or White Oak (bold texture)

- Luxury dark tones: Walnut (eliminates need for dark stain)

- Uniform color, budget: Alder (consistent stain absorption)

- Maximum durability: Hard Maple (hardest stainable wood, though prone to blotching)

Finish specification:

- Oil-based stain (deeper penetration, richer color)

- Gel stain for blotch-prone species (maple, birch)

- Pre-stain conditioner on closed-grain woods

- Polyurethane or lacquer topcoat with UV inhibitors

Budget-Conscious Projects (Rental Properties, Flips, Temporary Solutions)

Optimization strategy:

- Doors: MDF painted or thermofoil (cost-effective, durable finish)

- Boxes: Plywood for sink bases, quality particleboard for uppers acceptable

- Wood species: Birch for painted solid wood applications

- Hardware: Mid-tier soft-close (balance cost and durability)

- Expected lifespan: 10-15 years with proper installation

Where to maintain quality even in budget projects:

- Plywood sink bases (moisture protection)

- Soft-close hardware (prevents damage accumulation)

- Proper edge banding (moisture ingress prevention)

Premium Installations (Custom Homes, High-End Remodels, Luxury Market)

Specification standards:

- Boxes: Baltic Birch plywood throughout

- Doors: Solid hardwood (species based on design intent)

- Drawer construction: English dovetails with 5/8″ solid sides

- Hardware: Blum or Grass premium with heavy-duty ratings

- Finish: Hand-rubbed stain with multiple coats, or 2K polyurethane for painted

- Expected lifespan: 30-50+ years with refinishing capability

Professional Installation Considerations

Material quality means nothing without proper installation. Critical installation factors:

Pre-Installation Checklist

Material verification:

- ✅ All components acclimated 48-72 hours

- ✅ Moisture content compatible with installation environment

- ✅ CARB/TSCA compliance documentation on file

- ✅ All hardware present and correct specification

Site preparation:

- ✅ Walls plumb and level (critical for door alignment)

- ✅ Subfloor level within 1/4″ over 10 feet

- ✅ Relative humidity 35-50%

- ✅ Temperature 60-80°F during and after installation

Moisture protection:

- ✅ All plumbing connections verified leak-free

- ✅ Waterproof caulking available

- ✅ Under-sink areas inspected for previous water damage

- ✅ Ventilation systems operational

Installation Best Practices

Cabinet box installation:

- Level first cabinet in run; shim as necessary

- Attach cabinets to studs with 3″ screws (minimum 2 per cabinet)

- Clamp cabinets together before face-frame screws

- Verify doors clear before final fastening

- Caulk all gaps after installation

Door and drawer adjustment:

- Use six-way hinge adjustment for consistent reveals

- Target 1/8″ consistent gap around all doors

- Verify soft-close engagement on all hinges

- Test drawer slides for smooth operation and full extension

- Mark floor position for future base cabinet leveling

Moisture barrier installation:

- Caulk countertop-to-wall junction

- Seal around all sink cutouts (top and bottom)

- Caulk backsplash junction

- Install under-sink mats/liners

Warranty Considerations and Quality Assurance

Cabinet warranties provide insight into manufacturer confidence and expected lifespan.

Typical Warranty Structure

Coverage periods:

- Production cabinets: 1-5 years

- Semi-custom (Fabuwood): Limited lifetime (original purchaser)

- Custom cabinets: 5-10 years to limited lifetime

What’s typically covered:

- ✅ Materials defects (warping, delamination, joint failure)

- ✅ Workmanship defects (loose joints, poor fitting)

- ✅ Hardware defects (hinges, slides failing prematurely)

- ✅ Finish defects (peeling, bubbling, excessive checking)

What’s typically NOT covered:

- ❌ Improper installation

- ❌ Misuse or abuse

- ❌ Normal wear and tear

- ❌ Environmental damage (water exposure from leaks)

- ❌ Color variation in natural wood

- ❌ Wood movement (seasonal gap changes)

- ❌ Painted stress lines at joints (normal wood behavior)

Fabuwood Warranty Specifics

Coverage: Limited lifetime warranty for original purchaser while they own the home

Exclusions (per Fabuwood documentation):

- Environmental damage from humidity extremes or water exposure

- Improper installation or support

- Normal wear including painted cabinet stress lines at joints

- Modifications or repairs by unauthorized parties

Claims process:

- Document defect with photos

- Contact dealer/distributor

- Manufacturer evaluates claim

- Replacement parts shipped if approved

- Labor typically homeowner responsibility

Why lifetime warranty matters:

- Demonstrates manufacturer confidence in construction quality

- Provides recourse for legitimate defects

- Transfers value to home buyers (increases resale value)

- Industry-leading compared to 5-10 year alternatives

Frequently Asked Questions for Durable Shaker Cabinets

Material Selection

Should I choose solid wood or MDF for painted Shaker cabinets?

MDF outperforms solid wood for painted applications.

MDF’s uniform density eliminates grain telegraphing and prevents the hairline cracks that appear at rail-stile joints in painted solid wood. Modern premium manufacturers use hybrid construction—solid wood frames for structural rigidity and hinge mounting, with MDF center panels for dimensional stability and perfect paint surfaces.

Why does Fabuwood use MDF panels in their doors if they have Premium AWI certification?

This is engineering, not cost-cutting. MDF center panels prevent the expansion/contraction that causes joint cracking in solid wood panels during humidity changes. The solid birch frame provides superior structural integrity and screw-holding power for hinges, while the MDF panel delivers dimensional stability and a perfect substrate for durable paint finishes. This hybrid construction represents best-practice engineering for painted cabinetry.

Is plywood really necessary for cabinet boxes, or is particleboard acceptable?

Plywood is mandatory for sink bases and high-moisture areas; acceptable particleboard exists for other applications. Plywood’s cross-grain lamination provides superior moisture resistance, screw-holding power, and structural strength. Particleboard swells permanently when exposed to water and screws loosen over time. For budget projects, quality particleboard is acceptable for upper cabinets in controlled environments, but never for base cabinets near water sources.

What’s the difference between Baltic Birch and regular plywood?

Baltic Birch features all-birch construction with 11-13 plies versus 7-9 in standard plywood, creating void-free panels with superior screw-holding strength. The higher ply count provides exceptional dimensional stability and clean edge profiles suitable for exposed applications. The premium cost (approximately 35% above standard plywood) is justified for high-end custom work, wide frameless cabinets, and dovetail drawer construction.

Durability and Performance

How long should quality Shaker cabinets last?

Expected lifespan correlates directly with construction quality:

- Budget cabinets (particleboard boxes, stapled drawers): 10-15 years

- Mid-range cabinets (plywood boxes, dowel drawers): 15-25 years

- Premium cabinets (all-plywood, dovetail drawers): 30-50+ years with refinishing

Proper installation, moisture management, and maintenance significantly impact actual lifespan regardless of quality tier.

Why do painted cabinet joints sometimes crack?

Wood expands perpendicular to the grain when humidity increases. In a five-piece Shaker door, rails expand vertically while stiles don’t, creating stress at the joint. If the finish cannot stretch (low elasticity), it cracks at stress points. Solutions: (1) Use 2K polyurethane with high flexibility, (2) Specify MDF center panels that don’t expand significantly, (3) Use cope-and-stick joinery that accommodates movement, (4) Educate clients that minor seasonal gaps are normal wood behavior.

What makes Blum hardware worth the extra cost?

Cycle testing and proven longevity. Blum hinges are tested to 200,000 cycles versus the 25,000-cycle KCMA minimum—eight times the industry standard. This translates to 25+ years of smooth operation in active kitchens. The six-way adjustability maintains proper door alignment over decades, and the soft-close mechanism prevents the cumulative damage that loosens screws and joints. For contractors, this means fewer callbacks and warranty claims.

Can I use MDF in bathroom vanities?

Only with proper specifications. Standard MDF swells irreversibly when wet. For bathroom applications, specify:

(1) MR-MDF (moisture-resistant formulation with green-tinted core),

(2) HDF for superior moisture protection, or

(3) Seal all cut edges with primer and paint before assembly. Plywood or thermofoil remain safer choices for high-humidity bathrooms. Ensure proper exhaust ventilation (minimum 50 CFM) to manage ambient moisture.

Cost and Value

Where should I invest for maximum durability without blowing the budget?

Prioritize in this order:

- Plywood sink base boxes (prevents catastrophic moisture failure)

- Dovetail drawer construction (outlasts alternatives by 5-10x)

- Premium soft-close hardware (protects entire cabinet system from impact damage)

- Quality finish (2K polyurethane prevents crack repairs on painted cabinets)

- Solid wood where visible (can be optimized to budget species like birch)

How much should I budget for quality Shaker cabinets?

For a standard 10×10 kitchen:

- Budget tier: $4,000-8,000 (RTA or builder-grade)

- Mid-range tier (Fabuwood range): $8,000-18,000

- Premium tier: $18,000-35,000+

Price per linear foot ranges from $150 (budget) to $650 (upper mid-range) to $1,200+ (true custom). Remember to include installation ($800-2,000), countertops ($2,000-8,000+), and hardware/accessories ($300-1,500).

Is refinishing an option with different materials?

Refinishing capability:

- ✅ Solid wood: Can be sanded and refinished multiple times (3-5 refinishing cycles typical)

- ✅ Solid wood with veneer: Can be lightly sanded and refinished 1-2 times

- ⚠️ MDF: Can be repainted but cannot be sanded deeply (damages fiber structure)

- ❌ Thermofoil: Cannot be refinished; vinyl film cannot be removed without destroying substrate

- ❌ Laminate: Cannot be refinished

For long-term investment, solid wood stained cabinets offer maximum refinishing flexibility.

Installation and Maintenance

How do I protect cabinets in high-humidity environments?

Multi-layered protection strategy:

- Material selection: Plywood boxes, moisture-resistant doors (thermofoil, sealed solid wood, or MR-MDF)

- Ventilation: 100+ CFM exhaust venting to exterior (not recirculated)

- Humidity control: Maintain 35-50% relative humidity year-round

- Sealing: Waterproof caulking at all gaps and junctions

- Prompt cleanup: Wipe spills immediately, especially inside cabinets

For extreme humidity (coastal areas, poorly ventilated bathrooms), consider marine-grade plywood with phenolic resin adhesive.

Why do cabinet doors have gaps that change with seasons?

This is normal wood behavior, not a defect. Wood is hygroscopic—it absorbs moisture from air until reaching equilibrium. As humidity increases (summer), wood expands; as humidity decreases (winter with heating), wood contracts. This causes 1/16″-1/8″ gap variations around doors. Solutions: (1) Allow one complete heating/cooling season for full acclimation before judging “warping”, (2) Maintain consistent indoor humidity year-round, (3) Educate clients this is normal material behavior, not a quality issue.

How long after delivery should I wait before installing cabinets?

Minimum 48-72 hours of acclimation in the installation space. This allows wood moisture content to equilibrate with ambient conditions. Installing cabinets directly from climate-controlled warehouses into humid basements or poorly ventilated kitchens causes immediate expansion and door misalignment. Place cabinets in the installation room, keep them boxed (protects finishes), and let them adjust to the environment.

Fabuwood-Specific Questions

How does Fabuwood deliver premium features at mid-range pricing?

Efficient manufacturing and strategic positioning. Fabuwood achieves cost advantages through: (1) High-volume Newark, NJ facility with streamlined assembly, (2) Bulk purchasing of Blum hardware, (3) Semi-custom model with comprehensive but not unlimited options, (4) 2-4 week lead times versus 6-8+ weeks for competitors. They’ve achieved AWI Premium Grade certification (highest architectural woodwork standard) while maintaining pricing in the $400-650/linear foot range.

What makes Fabuwood’s AWI Premium Grade certification significant?

It’s the highest tier of the three-level AWI system (Economy < Custom < Premium). Testing validates that joints, frames, doors, and shelves meet demanding architectural specifications—tall pantry cabinets tested to support 2,250 pounds, for example. Few semi-custom manufacturers achieve Premium grade. Combined with KCMA certification (drawer cycling, finish durability, load testing), these dual certifications provide documentation satisfying commercial project requirements.

Does Fabuwood’s lifetime warranty really cover everything?

No—understand the exclusions. Fabuwood’s limited lifetime warranty covers materials and workmanship defects while the original purchaser owns the home. However, it excludes: environmental damage (water exposure, humidity extremes), improper installation, normal wear, painted stress lines at joints (normal wood behavior), and unauthorized repairs. Labor is typically homeowner responsibility—manufacturer provides replacement parts only. Still, lifetime coverage for material defects significantly exceeds typical 5-10 year competitor warranties.

Material Selection Quick Reference

For painted Shaker cabinets:

- Doors: Solid hardwood frames + HDF/MDF panels

- Boxes: Plywood (3/4″ sides, 1/2″ backs minimum)

- Finish: 2K polyurethane (flexibility prevents cracks)

- Hardware: Blum soft-close hinges and slides

For stained Shaker cabinets:

- Doors: Solid hardwood (species by aesthetic goal)

- Boxes: Plywood (showcases quality investment)

- Finish: Oil-based stain + polyurethane with UV inhibitors

- Hardware: Blum soft-close hinges and slides

For budget-conscious projects:

- Doors: MDF painted or thermofoil

- Boxes: Plywood sink bases, quality particleboard uppers

- Finish: Conversion varnish or quality paint

- Hardware: Mid-tier soft-close (balance cost/durability)

For premium installations:

- Doors: Solid hardwood (cherry, walnut, white oak)

- Boxes: Baltic Birch plywood throughout

- Drawers: English dovetails, 5/8″ solid sides

- Finish: Hand-rubbed stain or 2K polyurethane

- Hardware: Blum/Grass premium with heavy-duty ratings

Ready to Specify Durable Shaker Cabinets for Your Next Project?

At IST Cabinets, we specialize in helping contractors and designers specify cabinetry that delivers decades of reliable performance. Our expertise with Fabuwood’s AWI Premium Grade certified product lines ensures you’re working with materials that meet the highest architectural standards while maintaining competitive project budgets.

Why Work With IST Cabinets?

✅ Expert material consultation: We help you optimize specifications for performance and budget

✅ Fabuwood authorized dealer: Access to full Allure, Nexus, Galaxy, and Illume product lines

✅ Fast lead times: 2-4 weeks standard, 5-7 days expedited available

✅ Professional support: Technical specifications, installation guidance, and warranty assistance

✅ Competitive pricing: Volume purchasing advantages passed to contractors and designers

Get Your Project Started

📞 Contact our specification team today:

- Review your project requirements and material priorities

- Receive detailed specification sheets and material comparisons

- Get accurate pricing for your scope of work

- Access Fabuwood’s comprehensive door style and finish samples

📧 Email: [Your email]

📱 Phone: [Your phone]

🌐 Website: istcabinets.com

Special resources for contractors:

- Downloadable specification sheets for all Fabuwood product lines

- Material performance comparison matrices

- Installation best practices guides

- Warranty registration and claims assistance

Download Our Free Resources

1. Shaker Cabinet Material Specification Checklist

Fabuwood Resources:

- Fabuwood Allure Specifications Catalog (PDF)

- Complete Allure series specifications

- Door styles and finish options

- Cabinet construction details

- Hardware specifications

- Fabuwood Value Series Specifications (PDF)

- Budget-tier specifications

- Material construction details

- Dimension guides

- All Fabuwood Specification Books – USA Distributor

- Fabuwood Allure

- Fabuwood Illume (frameless)

- Fabuwood Value Premium

- Fabuwood Quest

- Technical specifications for all series

What’s Included:

- Component-by-component material selection guide

- Application-specific recommendations

- Cost optimization strategies

- Door style comparisons

- Hardware specifications

2. Fabuwood Construction Details & Certifications

Official Fabuwood Resources:

- Fabuwood Quality Standards Sheet (PDF)

- Complete quality specifications

- Construction standards documentation

- Material grade information

- Fabuwood Digital Brochure 2025

- Interactive digital catalog

- Complete product line overview

- Construction techniques

- Finishing processes

- Fabuwood Allure Series Page

- AWI Premium Grade certification details

- Construction features

- Solid wood face frames

- Dovetailed construction information

- Veneered plywood specifications

AWI Certification Information:

- AWI Premium Certification Announcement – Woodworking Network

- Official announcement of Fabuwood’s AWI Premium Grade

- Testing methodology

- Quality standards achieved

- AWI Standards Information

- Architectural Woodwork Institute standards

- Premium Grade requirements

- Industry benchmarks

What’s Included:

- Complete AWI Premium Grade specifications

- KCMA testing documentation details

- Hardware specifications and load ratings

- Construction detail diagrams

- Material composition breakdowns

3. Cabinet Installation Best Practices Guide

Fabuwood Installation Resources:

- Cabinet Size & Dimension Guide – Fabuwood

- Standard cabinet dimensions

- Space planning guidelines

- Clearance requirements

- PDF download available

- Installation Guides – Cabinet Makers Choice

- Frameless installation guides

- Fabuwood-specific tutorials

- Step-by-step instructions

What’s Included:

- Pre-installation preparation checklist

- Moisture protection protocols

- Adjustment and alignment procedures

- Level and plumb requirements

- Cabinet anchoring specifications

- Door adjustment instructions

4. Warranty Guide & Claims Process

Official Fabuwood Warranty Documentation:

- Fabuwood Warranty Page (Official)

- Limited lifetime warranty details (Allure, Illume, Nexus, Fusion series)

- 5-year warranty details (Quest, Value series)

- Coverage limitations and exclusions

- Warranty terms and conditions

- Fabuwood 5-Year Limited Warranty (PDF)

- Detailed warranty document

- Coverage specifications

- Claim procedures

- Fabuwood Warranty Information – USA Distributor

- Warranty details by series

- Registration information

- Claims process overview

What’s Included:

- Coverage details and exclusions

- Claims documentation requirements

- Common issues and resolutions

- What’s covered vs. what’s not

- Registration requirements

- RMA (Return Merchandise Authorization) process

5. Cabinet Care & Maintenance Guide

Fabuwood Care Resources:

- Cabinet Care – Fabuwood Official

- Official care instructions

- Cleaning guidelines

- Maintenance best practices

- Cabinet Care Guide (PDF) – KSI Kitchen & Bath

- Downloadable PDF guide

- Detailed cleaning instructions

- Stain and finish protection

- Do’s and don’ts

What’s Included:

- Daily cleaning recommendations

- Approved cleaning products

- Stain removal techniques

- Moisture protection strategies

- Finish preservation guidelines

- What to avoid

Complete Resource Library

All Resources Available at:

Conclusion: Engineering Durability Into Every Project

Selecting materials for durable Shaker cabinets requires understanding how component-level properties—hardness, moisture resistance, dimensional stability, finish compatibility—translate into system-level performance over decades of daily use.

Plywood provides the structural foundation for cabinet boxes due to superior strength and moisture resistance. Door material selection depends primarily on finish choice: MDF for painted surfaces delivers superior results, while hardwoods showcase natural beauty in stained applications. Thermofoil offers budget-conscious moisture resistance for specific applications.

Quality construction details—dovetail drawer joinery, cope-and-stick door frames, captured back panels, and premium hardware—distinguish investment-grade cabinetry from economy alternatives. These elements command premium costs but deliver longevity that justifies initial investment through decades of reliable service.

Fabuwood’s achievement of AWI Premium Grade certification while maintaining semi-custom pricing demonstrates that quality construction need not command custom pricing. Their all-plywood boxes, dovetail drawers, solid wood frames, and Blum hardware deliver premium durability at competitive mid-range pricing.

Environmental factors—humidity control, ventilation management, prompt spill cleanup—significantly impact material performance regardless of quality level. Proper installation practices protect material investments and extend functional lifespans from 10-15 years to 25-30+ years.

Ultimately, durable Shaker cabinets result from systematic material selection aligned with specific use conditions, aesthetic priorities, and budget constraints. Whether specifying economy cabinets for rental properties or premium installations for luxury homes, applying these material selection principles ensures Shaker cabinets that deliver reliable service consistent with their intended application and price point.

About IST Cabinets

IST Cabinets serves Northern Virginia, Maryland, and the greater DMV area with professional-grade cabinetry solutions for contractors, designers, and remodelers. As an authorized Fabuwood dealer, we provide access to AWI Premium Grade certified product lines with industry-leading durability specifications. Our team combines material expertise, competitive pricing, and fast lead times to support projects of all scales.

Contact us today to discuss your next Shaker cabinet project or Join our Loyalty Program to gain benefits for every Fabuwood purchase.

Last updated: January 2026 Keywords: shaker cabinets, cabinet materials, Fabuwood cabinets, cabinet durability, plywood vs MDF, dovetail drawers, Blum hardware, AWI certification, cabinet construction, kitchen remodeling