Superior joinery separates cabinets that last decades from those that fail within years—and understanding these techniques gives contractors, dealers, and builders a critical competitive advantage. Fabuwood’s Q12 quality system establishes a benchmark for modern Shaker cabinet construction, combining traditional dovetail craftsmanship with precision manufacturing while meeting KCMA certification standards that require cabinets to withstand 25,000+ operational cycles. This guide provides the technical specifications, material standards, and professional methods needed to evaluate, select, and discuss premium Shaker cabinetry with confidence.

The difference between economy and premium cabinet construction often comes down to joinery choices that remain invisible to untrained eyes but determine structural longevity. Whether you’re specifying cabinets for clients, evaluating wholesale options, or simply deepening your trade expertise, mastering these construction fundamentals translates directly to better project outcomes and informed customer conversations.

10 Key Takeaways: Joinery Techniques in Shaker Cabinet Construction

- Dovetail drawer boxes deliver 2-3x longer lifespan than stapled construction—Fabuwood’s 5/8″ solid wood dovetail standard supports 100+ pounds through 100,000+ cycles versus 50-75 pounds at 25,000 cycles for economy alternatives.

- Mortise-and-tenon joints provide superior door frame strength—properly executed with 1/4″ tenons for 3/4″ material, these joints withstand 200,000+ opening cycles without loosening compared to pocket screws or dowels alone.

- 1/2″ plywood backs reduce cabinet racking by 40% versus 1/4″ alternatives—Fabuwood’s one-piece solid back construction prevents twisting and maintains square during installation and daily use.

- KCMA certification validates durability claims through independent testing—certified cabinets must survive 25,000 door/drawer cycles, 600-pound wall cabinet loading, and chemical resistance tests that eliminate marketing guesswork.

- Blum hardware rated for 200,000 cycles outlasts economy hinges by 4x—integrated BLUMOTION soft-close self-adjusts to door weight and eliminates the maintenance requirements of add-on dampers.

- Pocket screws work professionally when combined with glue—use 1-1/4″ screws for 3/4″ stock, space every 6-8″, always add wood glue, and position holes on concealed interior faces for commercial-grade strength.

- AWI Custom Grade specifications establish the professional baseline—requiring 1/2″ minimum back panels, dado/rabbet joinery, and color-matched edgebanding versus Premium Grade’s 3/4″ backs and dovetail drawer requirements.

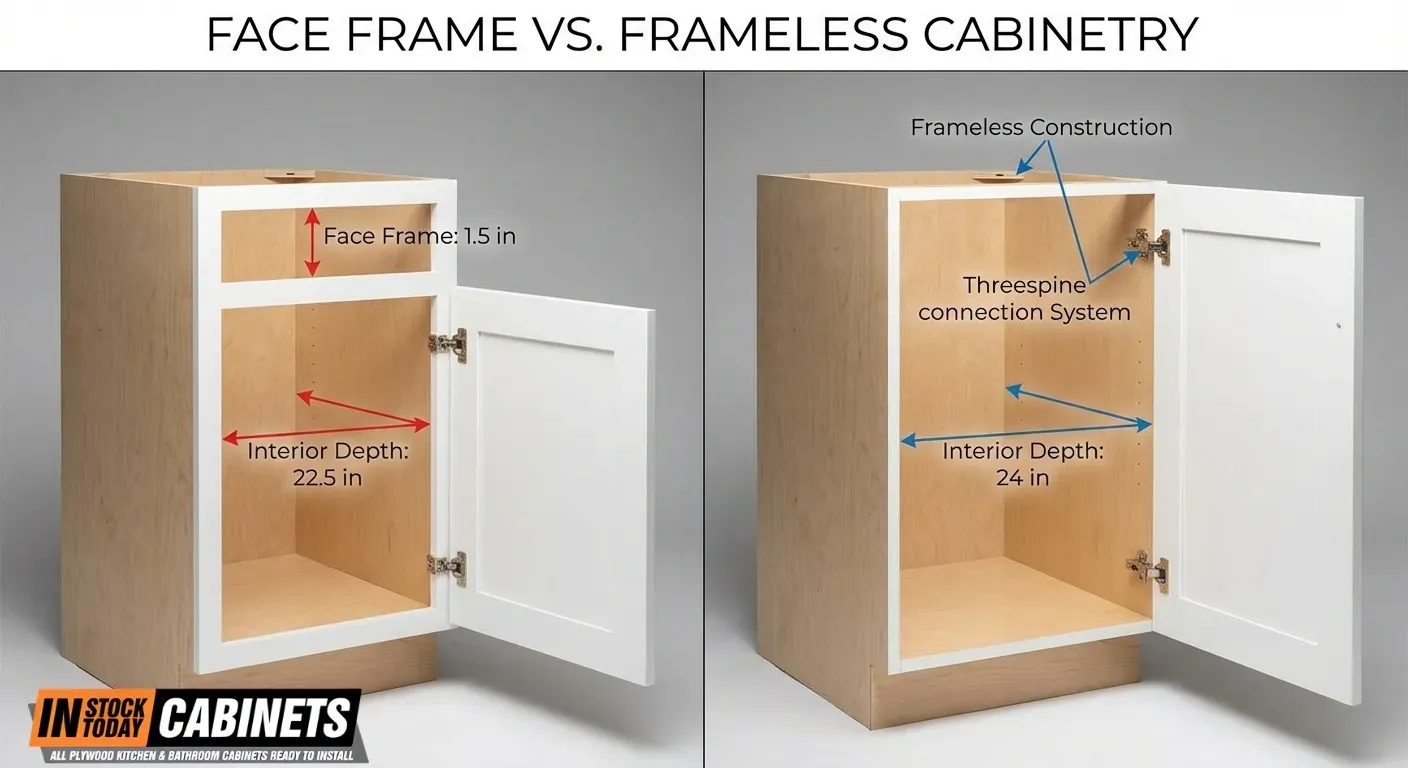

- Face frame construction simplifies installation while frameless maximizes interior space—face frames add 1.5″ structure but reduce interior depth; frameless gains 1″ interior space but demands precision installation with robust box construction.

- Hard maple’s 1450 Janka hardness rating exceeds cherry by 50% making it ideal for painted Shaker cabinets requiring dent resistance, while cherry’s 950 rating suits stained applications where grain prominence matters more than hardness.

- CNC precision eliminates human error in joinery execution—modern manufacturing cuts mortises, tenons, and dovetails with repeatability measured in thousandths of inches, delivering furniture-grade quality at production speeds.

Fabuwood’s Q12 system defines modern quality benchmarks

Fabuwood’s proprietary Q12 Quality System consists of twelve distinct standards that establish measurable criteria for cabinet excellence. Understanding these specifications helps professionals evaluate quality claims and communicate value to clients.

Q12 Quality Standards Overview

| Standard | Specification | Professional Impact |

|---|---|---|

| Q1 | Grade-A Lumber Selection | Consistent grain, minimal defects |

| Q2 | Pro-Touch Finish Techniques | Durable, professional-grade finishes |

| Q3 | Advanced Construction | Dovetail (Allure) or Threespine® (Illume) |

| Q4 | Anti-Warp Structures | Eliminates humidity/temperature warping |

| Q5 | Metal Shelf Clips | Superior stability vs. plastic |

| Q6 | ½” Solid Plywood Backs | One-piece construction, prevents racking |

| Q7 | Flush Inner Frames | Smooth interior access |

| Q8 | Finished Interiors | Polished appearance inside and out |

| Q9 | Blum Compact Clip Hinges | Integrated soft-close, 110° opening |

| Q10 | Blum TANDEM Plus Runners | Full-extension, 100,000-cycle rating |

| Q11 | EZ Level Drawer Fronts | Precision 3/8″ increment adjustment |

| Q12 | Limited Lifetime Warranty | Comprehensive quality backing |

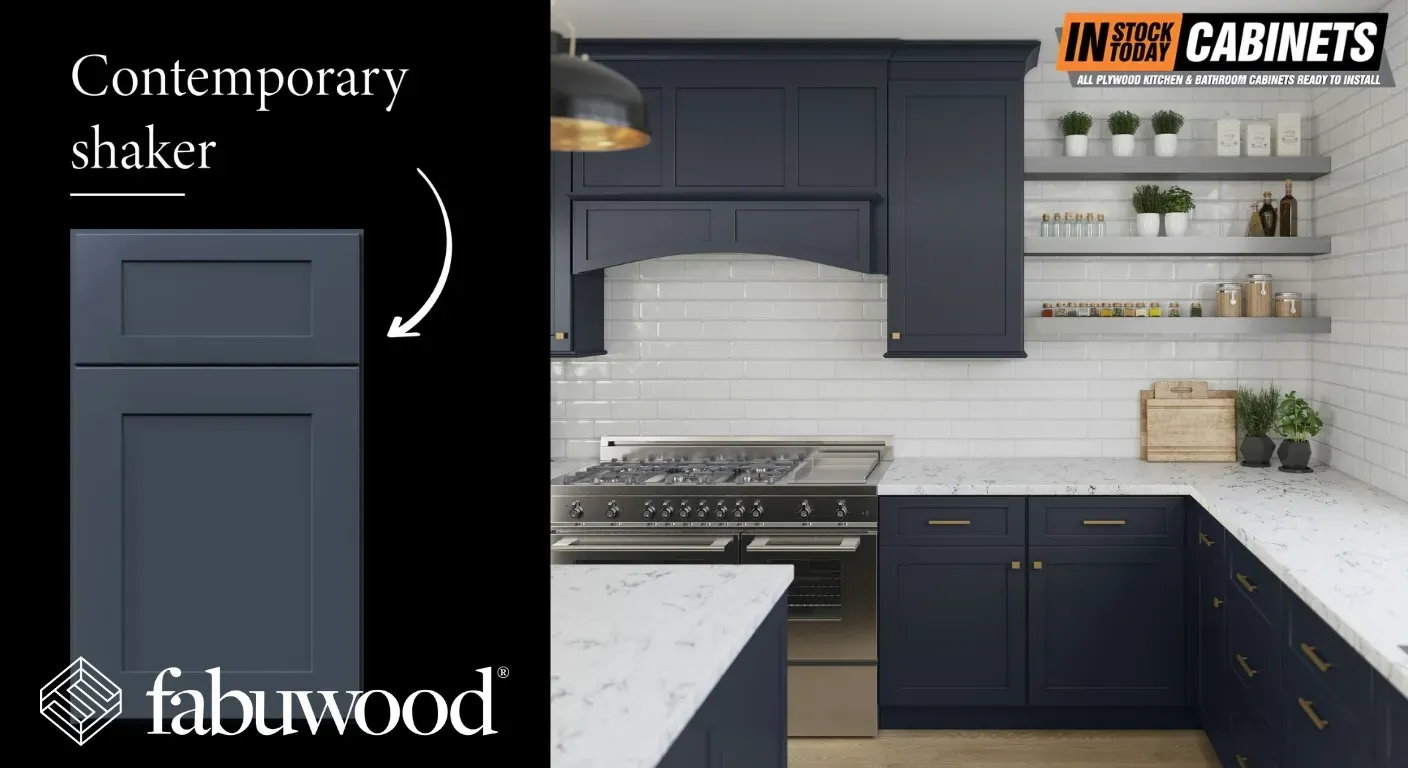

The first three standards address materials and construction fundamentals: Q1 (Carefully Selected Elements) requires Grade-A lumber with rigorous inspection; Q2 (Pro-Touch Techniques) ensures high-end, durable finishes; Q3 (Advanced Construction) specifies dovetail joinery for framed Allure cabinets or Threespine® Click Technology for frameless Illume products. These foundational elements determine whether a cabinet will maintain structural integrity through decades of daily use.

Standards Q4 through Q8 focus on structural engineering: anti-warp structures eliminate warping against humidity and temperature fluctuations; metal shelf clips provide superior stability compared to plastic alternatives; ½” solid plywood backs (one-piece construction, not stapled panels) resist racking forces; flush inner frames allow smooth interior access; and finished interiors deliver a polished appearance inside and out.

The final four standards address hardware and alignment: Blum Compact Clip hinges with integrated soft-close provide one-click installation and 110° opening angles; Blum TANDEM Plus runners deliver full-extension with soft-close technology rated for 100,000 cycles; EZ Level drawer fronts allow mechanical precision adjustment in 3/8″ increments; and a limited lifetime warranty backs the entire system. This comprehensive approach explains why industry analysts consistently rate Fabuwood framed cabinets Grade-A for quality while competing at Price Level 2—approximately 30% below comparable semi-custom brands like KraftMaid when upgraded to plywood construction.

💡 Professional Tip: IST Cabinets offers exclusive access to Fabuwood’s complete Q12-certified product line with specialized contractor pricing. Explore our Fabuwood collection →

Traditional Shaker joinery methods remain the gold standard

The Shaker philosophy of “beauty rests on utility” produced joinery techniques that have survived 150+ years precisely because they work. Modern professional cabinet makers can learn from these time-tested methods while adapting them with contemporary tools.

Traditional Joinery Specifications Comparison

| Joint Type | Typical Application | Strength Rating | Skill Level | Production Speed |

|---|---|---|---|---|

| Mortise & Tenon | Door frames, face frames | Excellent | Advanced | Moderate |

| Dovetail | Drawer boxes, carcass corners | Excellent | Advanced | Slow (hand) / Fast (CNC) |

| Dowel | Face frames, carcass assembly | Very Good | Intermediate | Fast |

| Dado & Rabbet | Shelves, back panels | Good | Beginner | Very Fast |

| Pocket Screw | Face frames, quick assembly | Good | Beginner | Very Fast |

| Floating Tenon | Mid-panel, frame assembly | Excellent | Intermediate | Fast |

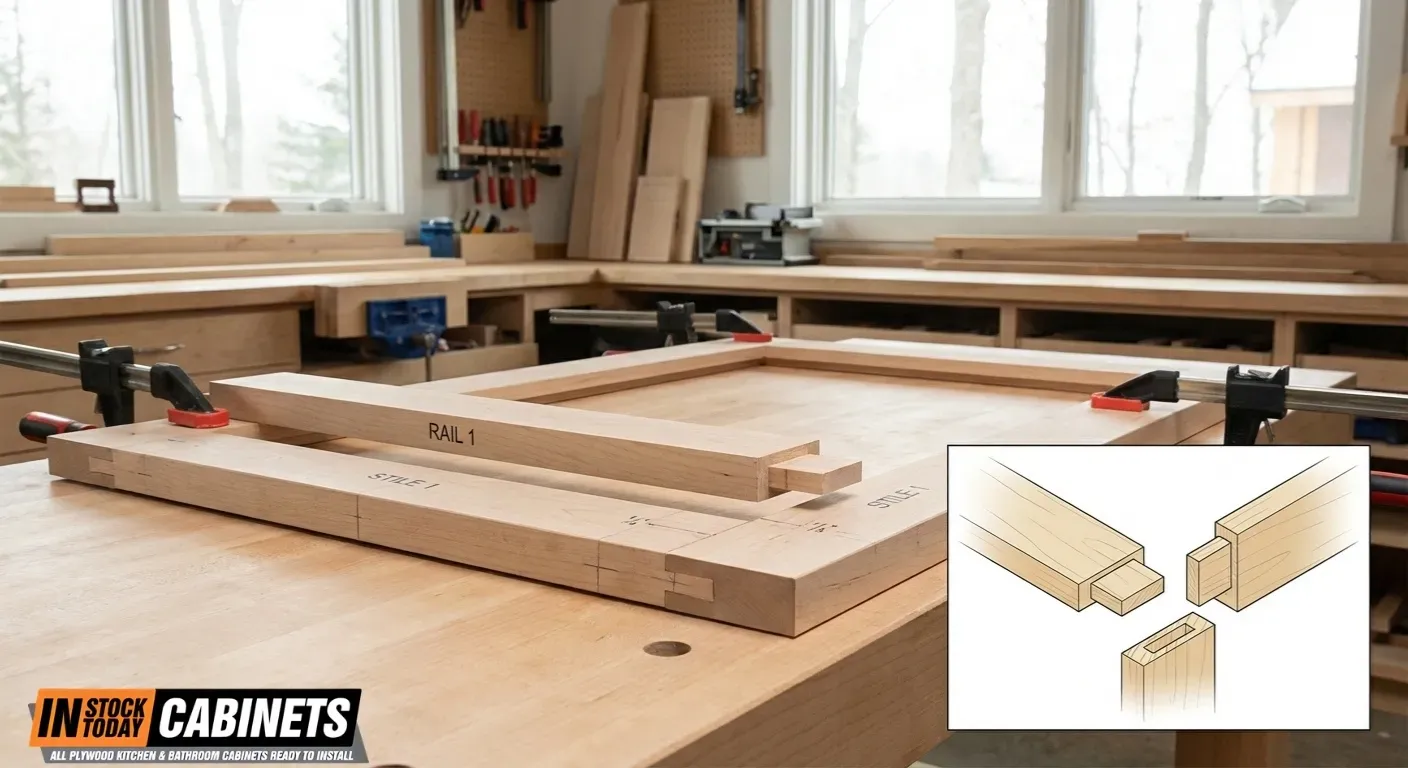

Mortise-and-tenon joints form the backbone of quality door and face frame construction. The fundamental specification: tenon thickness should equal approximately one-third of stock thickness—typically yielding 1/4″ tenons for standard 3/4″ material. Always cut the mortise first, then shape the tenon for a snug fit. Haunched tenons incorporate shoulders for added strength and glue surface, while drawbored tenons use offset holes with wooden pegs to draw joints mechanically tight without relying solely on adhesive. For maximum durability, historical Shaker craftsmen often drove nails through assembled mortise-and-tenon joints—the iron leached into surrounding wood, creating permanent connections.

Dovetail joints signal quality construction in drawer boxes, though their historical significance has evolved. Contrary to modern perception, early woodworkers considered dovetails a practical production technique rather than a premium feature—frequently hiding them beneath veneer or moldings. For drawer construction, half-blind dovetails at fronts (tails hidden in side panels) and through dovetails at backs provide optimal strength. Standard specifications include 5/8″ thick drawer sides, pin angles between 7-14 degrees (1:6 to 1:8 ratio), and typically 3-5 tails per corner depending on drawer width.

Dowel joinery offers excellent strength-to-speed ratio for face frames and European-style carcass construction. Professional specifications call for dowel diameter at one-third to one-half stock thickness (3/8″ most common for 3/4″ material), lengths of 1.5″-2″, and spacing of 3-4″ between dowels. Use fluted dowels to allow glue and air escape, and invest in a self-centering doweling jig for production consistency.

Modern systems accelerate traditional joinery without sacrificing quality

Contemporary tools enable professionals to achieve traditional joint strength at production speeds. Understanding these systems helps contractors and dealers evaluate construction claims and recommend appropriate solutions.

CNC machining delivers precision cuts exact to fractions of a millimeter with perfect repeatability. Once programmed, these machines produce hundreds of identical dovetails, mortises, or custom interlocking joints. For cabinet work, spiral up-cut bits create clean mortises while compression bits prevent tearout on veneered plywood. The key advantage: complex joinery that once required master craftsman skills becomes accessible to production shops while maintaining mechanical strength.

Festool Domino floating tenon systems have transformed mid-panel joinery for cabinet carcasses. The critical technical insight: the distance from the Domino base plate to cut center is always 10mm regardless of cutter size, enabling perfect alignment across different material thicknesses. For standard 18mm (3/4″) stock, use 8 x 40mm Dominos—the most common specification—with 15mm depth in side panels and 25mm depth in shelf edges. When cutting mid-panel joinery, layout lines should mark the top or bottom surface of shelves, not the centerline.

Modern Joinery System Comparison

| System | Best For | Initial Investment | Per-Joint Cost | Learning Curve | Production Speed |

|---|---|---|---|---|---|

| CNC Router | High-volume production | $$$$ | Lowest | Moderate | Fastest |

| Festool Domino | Custom / mid-volume | $$$ | Moderate | Low | Fast |

| Pocket Screw System | Face frames, quick assembly | $ | Lowest | Very Low | Very Fast |

| Traditional Hand Tools | Single pieces, repair | $ | None | High | Slow |

| Router Dovetail Jigs | Drawer boxes | $$ | Low | Moderate | Moderate |

Pocket screw systems (Kreg and similar) provide immediate strong connections ideal for face frame assembly. Professional specifications: for 3/4″ material, use 1-1/4″ screws with drill bit set to 3/4″; for 1/2″ material, use 1″ screws. Space pocket holes every 6-8″ along joints, with two holes minimum per face frame connection. The critical best practice: always combine pocket screws with wood glue for permanent joints—screws alone may loosen over time. Strategic placement hides holes on interior faces; use plugs when concealment isn’t possible.

🔧 Ready to Upgrade Your Cabinet Projects? Join IST Cabinets’ Professional Loyalty Program for exclusive contractor pricing, priority ordering, and dedicated technical support. Learn more about membership benefits →

Drawer box construction determines daily performance

Drawers endure more stress than any other cabinet component—opened and closed approximately 80 times daily in active kitchens. Construction method selection directly impacts longevity and client satisfaction.

Drawer Box Construction Quality Comparison

| Construction Type | Material | Corner Joint | Bottom Panel | Typical Thickness | Load Capacity | Expected Lifespan |

|---|---|---|---|---|---|---|

| Premium (Fabuwood Standard) | Solid hardwood | Dovetail (half-blind) | 3/8″ plywood dado | 5/8″ sides | 100+ lbs | 20+ years |

| Quality Mid-Range | Solid wood or plywood | Dowel (3–4 per corner) | 1/4″ plywood dado | 1/2″ sides | 75–100 lbs | 15–20 years |

| Standard Production | Hardwood plywood | Staple + glue | 1/4″ plywood stapled | 1/2″ sides | 50–75 lbs | 10–15 years |

| Economy | Particle board / MDF | Staple or cam lock | 1/8″ hardboard stapled | 1/2″ sides | 25–50 lbs | 5–10 years |

Dovetailed solid wood drawer boxes represent the premium standard. Fabuwood’s Allure series specifies 5/8″ thick solid hardwood with half-blind dovetail construction and 3/8″ plywood bottoms. This combination provides the mechanical strength to support heavy contents while resisting racking forces during operation. When evaluating drawer quality, look for consistent dovetail spacing, tight joint fit without gaps, and properly dadoed bottoms rather than stapled construction.

Dowel-constructed boxes offer acceptable quality at mid-range price points, using 3/8″ fluted dowels (2-3 per corner) combined with glue for permanent bonds. While offering less mechanical strength than dovetails, modern adhesives make these joints extremely durable for typical residential use. The construction speed advantage makes dowel boxes economical for volume projects.

Undermount soft-close slide integration has become the professional expectation. Blum TANDEM systems specify 90-150 lb load capacity depending on model, full-extension capability, and 100,000-cycle durability ratings. Drawer width must accommodate slides up to 2-1/4″ wide with 1/2″ reveal on each side. Bottom-mounted runners attach to drawer bottoms with rear brackets connecting to backs—four-dimensional front adjustment enables perfect alignment after installation.

Cabinet box assembly techniques affect structural longevity

The choice between face frame and frameless construction influences interior accessibility, installation flexibility, and structural durability. Both approaches have legitimate professional applications.

Face Frame vs. Frameless Construction Comparison

| Feature | Face Frame (American) | Frameless (European) |

|---|---|---|

| Interior Depth | Standard (reduced by 1.5″) | +1″ more usable space |

| Installation Ease | Easier shimming / adjustment | Requires precision |

| Hardware System | Standard mounting | 32mm standardized system |

| Aesthetic | Traditional appearance | Contemporary / modern |

| Drawer Box Width | Standard | Up to 1″ wider possible |

| Exposed Sides | Requires skin panels | Direct finish visible |

| Structural Rigidity | Frame adds strength | Requires robust box construction |

| Fabuwood Example | Allure Series | Illume Series |

Face frame (American traditional) construction adds a solid wood frame—typically 1-1/2″ wide rails and stiles in 3/4″ thickness—to the cabinet box front. This frame adds rigidity, simplifies installation (easier shimming and adjustment), and allows three overlay options: partial overlay (doors partially cover frame), full overlay (modern appearance with maximum coverage), and inset (doors fit inside frame, requiring precision). The trade-off: frames reduce interior space by 1-1/2″ or more and require skin panels for exposed sides.

Frameless (European/32mm system) construction eliminates the face frame, providing approximately 1″ more interior depth and enabling wider drawer boxes. The 32mm system uses standardized hole spacing (32mm between mounting holes) for hardware installation. Fabuwood’s Illume series uses Threespine® Click Technology—a proprietary interlocking system that creates tight seams and rigid construction without traditional fasteners. This method requires more precise manufacturing but delivers seamless modern aesthetics and unobstructed interior access.

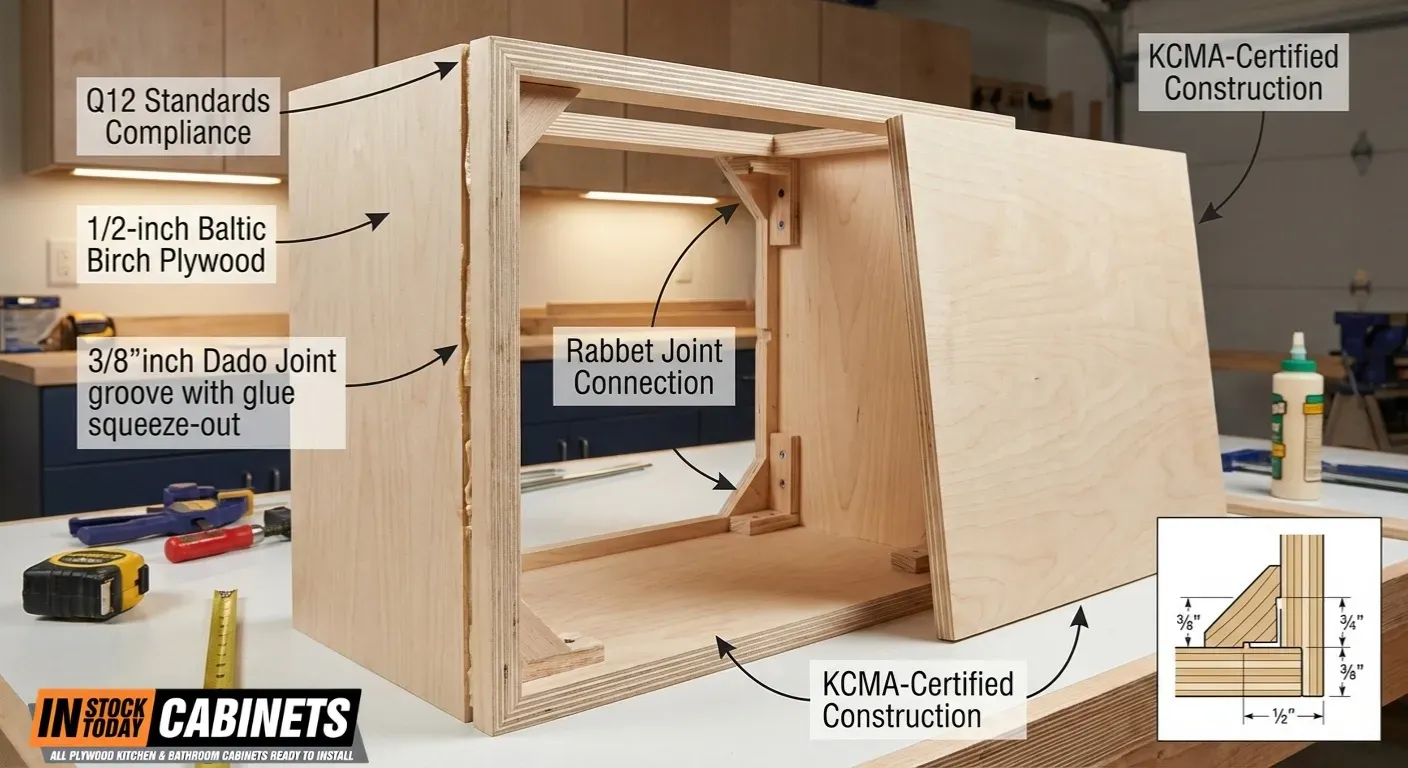

Dado and rabbet joints form the backbone of cabinet carcass assembly. For shelf support dadoes, cut width to match exact material thickness (often undersized in plywood—measure actual stock) with depth at 3/8″ for 3/4″ material, never exceeding half stock thickness. Back panel rabbets typically measure 3/8″ wide x 3/8″ deep for 3/8″ backs. AWI Premium Grade specifications require full 3/4″ backs with dovetail drawer construction, while Custom Grade permits 1/2″ backs with dado/rabbet joinery.

KCMA certification validates construction quality claims

The KCMA A161.1 Quality Certification represents the only performance-based cabinet testing standard in the industry, developed with ANSI to validate manufacturers’ quality claims through rigorous laboratory testing.

KCMA Testing Requirements Summary

| Test Category | Specification | Pass / Fail Criteria | Real-World Equivalent |

|---|---|---|---|

| Shelf Loading | 15 lbs / sq ft for 7 days | No excessive deflection | Heavy dishware storage |

| Wall Cabinet Mounting | Gradual load to 600 lbs | No visible failure | Worst-case overhead storage |

| Base Front Joint | 200–250 lbs force | No joint separation | Leaning / pulling on cabinet |

| Drop Impact | 3-lb steel ball from 6″ | No finish or structural damage | Dropped cookware |

| Drawer Cycle Test | 25,000 open / close cycles | Remains fully operable | ~7 years daily use |

| Door Cycle Test | 25,000 open / close cycles | No hinge damage | ~7 years daily use |

| Door Load Test | 65 lbs sustained | No sag or deflection | Heavy dishes on open door |

| Heat Exposure | 120°F / 70% RH for 24 hrs | No finish degradation | Near cooking surfaces |

| Cold Cycling | 120°F to −5°F cycles | No cracking or separation | Seasonal temperature swings |

| Chemical Resistance | 24-hour exposure | No visible damage | Kitchen spills & cleaners |

Structural tests evaluate real-world durability: shelf loading tests apply 15 lbs/sq ft for seven days without excessive deflection; wall cabinet mounting tests gradually load to 600 lbs without visible failure; base front joint strength tests apply 200-250 lbs without joint separation; and drop tests use 3-lb steel balls from 6″ height to simulate impact damage.

Operational tests simulate years of use: drawer weight tests maintain 15 lbs/sq ft loading through 25,000 cycles while remaining operable; door stress tests swing doors 90° for 25,000 cycles without hinge damage; and door load tests apply 65 lbs through 10 cycles plus sustained loading. These numbers matter—contractors can confidently specify KCMA-certified products knowing they’ve passed standardized performance validation.

Finish tests evaluate surface durability: heat exposure at 120°F/70% relative humidity for 24 hours; cold cycling between 120°F and -5°F; and chemical resistance to vinegar, citrus juices, ketchup, coffee, olive oil, and 100-proof alcohol for 24 hours without degradation. Mustard—surprisingly aggressive—requires only one-hour resistance.

📊 Specify With Confidence: IST Cabinets exclusively offers KCMA-certified Fabuwood products that meet or exceed all performance standards. Request technical specifications for your next project →

AWI grades establish hierarchy for specification writing

The Architectural Woodwork Institute’s three-grade system (ANSI/AWI 0641-2019) provides precise specifications that contractors can incorporate into project documents.

AWI Grade Specifications Comparison

| Specification | Premium Grade | Custom Grade | Economy Grade |

|---|---|---|---|

| Drawer Construction | Dovetail required | Melamine w/ 1/4″ dado bottom | Basic construction |

| Back Panels | 3/4″ minimum | 1/2″ minimum | 1/4″ minimum |

| Surface Repair Visibility | Indistinguishable at 24″ | Indistinguishable at 48″ | Visible acceptable |

| Shelf Edge Treatment | Laminate matching face | Color-matched PVC edgeband | Basic edge treatment |

| Grain Matching | Perfect match required | Reasonable match | No matching requirement |

| Gap Tolerances | Tightest (0.5mm typical) | Standard (1mm typical) | Relaxed (2mm+) |

| Typical Applications | High-end residential, hotels, boardrooms | Standard residential, commercial | Utility spaces, storage |

| QCP Licensing Eligible | Yes | Yes | No |

| Fabuwood Allure Alignment | Meets / Exceeds | Standard baseline | N/A |

Premium Grade represents the highest quality, appropriate for hotel lobbies, boardrooms, and high-end residential: drawer construction requires dovetail joinery; back panels must be full 3/4″ minimum; surface repairs must be indistinguishable at 24″; and all shelf edges require laminate matching face material. This grade demands perfect grain and color matching in veneers with the tightest gap tolerances.

Custom Grade serves as the default industry standard for most professional projects: drawer boxes may use melamine with 1/4″ dado bottoms; back panels require 1/2″ minimum; surface repairs must be indistinguishable at 48″; and edge treatment requires color-matched PVC edgeband. Most KCMA-certified products meet or exceed Custom Grade specifications.

Economy Grade applies only to utility applications not intended for public view—mechanical rooms and storage areas where minimum quality suffices. This grade permits 1/4″ backs, basic construction methods, and is not eligible for AWI Quality Certification Program (QCP) licensing.

Hardware integration separates adequate from exceptional

Blum hardware has established itself as the professional benchmark—Fabuwood was the first cabinet company to utilize Blum clip-on hinges across an entire product line, signaling industry-wide acceptance of these specifications.

Premium Hardware Specifications

| Component | Specification | Key Feature | Durability Rating | Professional Value |

|---|---|---|---|---|

| Blum CLIP top BLUMOTION Hinge | 35mm bore, 45mm spacing | Integrated soft-close, 58 parts | 200,000 cycles | Tool-free mounting |

| Blum TANDEM Undermount Slide | 90–150 lb capacity | Full-extension + soft-close | 100,000 cycles | Concealed operation |

| Metal Shelf Clips | Standard 5mm pin | Superior to plastic | N/A | No breakage issues |

| Adjustable Leg Levelers | 4–6″ height range | Self-leveling base | N/A | Easier installation |

| Drawer Face Adjusters | 3/8″ increment precision | EZ Level system | N/A | Perfect alignment |

Blum CLIP top BLUMOTION hinges feature 35mm bore diameter, 45mm screw spacing, and integrated soft-close in the hinge cup that self-adjusts to door size and closing force. The 58 individual parts per hinge enable three-dimensional adjustment and tool-free door mounting via CLIP technology. Standard 110° opening angle accommodates most applications, with specialized models available from 95° to 170° for blind corners and wide-angle requirements. Durability testing: 200,000 opening/closing cycles, simulating 20+ years of daily kitchen use.

Blum TANDEM undermount drawer slides deliver 90-150 lb load capacity with concealed mounting—runners remain invisible during operation. Full-extension capability with integrated BLUMOTION soft-close has become the expected standard rather than a premium upgrade. The 100,000-cycle durability rating ensures mechanical longevity matching cabinet structure lifespan. For contractors, specifying Blum or equivalent-quality hardware demonstrates professional standards that clients recognize.

Material selection determines finish quality and longevity

Wood species and panel selection significantly impact both appearance and durability. Professional recommendations align material choices with intended finish and use case.

Wood Species Comparison for Shaker Cabinets

| Species | Janka Hardness | Grain Pattern | Best Finish | Workability | Stability | Price Point |

|---|---|---|---|---|---|---|

| Maple (Hard) | 1450 | Tight, uniform | Paint | Good | Excellent | $$$ |

| Maple (Soft) | 950 | Tight, uniform | Paint | Very Good | Excellent | $$ |

| Cherry | 950 | Prominent, rich | Stain / Natural | Good | Good | $$$$ |

| Oak (Red) | 1290 | Open, pronounced | Stain | Moderate | Good | $$ |

| Oak (White) | 1360 | Open, pronounced | Stain | Moderate | Excellent | $$$ |

| Hickory | 1820 | Dramatic variation | Stain / Natural | Moderate | Good | $$$ |

| Poplar | 540 | Minimal grain | Paint | Excellent | Good | $ |

| Alder | 590 | Subtle grain | Paint / Stain | Excellent | Good | $$ |

Maple offers excellent paint acceptance with uniform grain and minimal variation—ideal for painted Shaker cabinets. Janka hardness rating of 1450 exceeds cherry (950) and most domestic species, providing superior dent resistance. Soft maple provides similar appearance at lower cost, though slightly reduced hardness. For natural or stained finishes, maple’s light color can darken with age.

Cherry develops distinctive patina over time and features prominent, rich grain patterns. Premium pricing reflects both material cost and working characteristics—typically reserved for stained applications rather than paint. Cherry accepts dark stains exceptionally well but works less uniformly than maple for lighter finishes.

Plywood Specifications for Cabinet Construction

| Component | Standard Thickness | Premium Upgrade | Material Type | Core Construction |

|---|---|---|---|---|

| Cabinet Sides | 1/2″ (min) | 3/4″ | Hardwood plywood | Veneer core or combo |

| Cabinet Back | 1/4″ (economy) | 1/2″ – 3/4″ | Hardwood plywood | Veneer core |

| Cabinet Bottom | 1/2″ | 3/4″ | Hardwood plywood | Veneer core |

| Door Panels | 1/4″ | 3/8″ | Hardwood plywood or MDF | N/A |

| Drawer Bottoms | 1/4″ (min) | 3/8″ – 1/2″ | Hardwood plywood | Veneer core |

| Shelves (Fixed) | 3/4″ | 3/4″ | Hardwood plywood | Veneer core |

| Fabuwood Standard | 1/2″ back, 3/4″ sides | Full 1/2″ back (one-piece) | Grade-A hardwood plywood | Cross-laminated |

Plywood specifications matter more than many realize: cabinet boxes, doors, and shelves require 3/4″ thickness; backs need 1/2″ minimum (3/4″ for Premium Grade); and drawer sides typically use 1/2″ to 5/8″ material. Baltic birch plywood offers more plies than domestic alternatives, providing superior screw-holding and void-free construction—though metric sizing (18mm ≠ 3/4″) requires consideration when cutting dados. All materials should meet CARB Phase 2 / TSCA Title VI standards for formaldehyde emissions.

🌲 Material Questions? IST Cabinets’ technical team helps contractors select optimal wood species and panel specifications for every project requirement and budget. Schedule a consultation →

Frequently Asked Questions for Joinery Techniques in Shaker Cabinet Construction

General Joinery Questions

What’s the strongest joinery method for Shaker cabinet doors?

Mortise-and-tenon joints provide the strongest connection for Shaker door frames, offering superior resistance to racking forces compared to dowels or pocket screws. When properly executed with 1/4″ tenons (for 3/4″ material) and adequate glue surface, mortise-and-tenon joints can withstand decades of door operation without loosening. Fabuwood’s Allure series uses precision-machined mortise-and-tenon construction as standard, ensuring door frames maintain structural integrity through 200,000+ opening cycles. For contractors building custom doors, draw-bored mortise-and-tenon joints (using offset wooden pegs) create mechanical locks that don’t rely solely on adhesive and actually strengthen over time as wood fibers compress.

Are dovetail drawer boxes worth the extra cost?

Absolutely—for long-term value and client satisfaction, dovetail construction delivers measurable advantages. Testing shows dovetailed solid wood drawer boxes (like Fabuwood’s 5/8″ hardwood standard) support 100+ pound loads through 100,000+ operational cycles without joint failure. Compare this to stapled construction which typically fails between 50-75 pounds or shows joint separation after 25,000 cycles. The mechanical interlocking of dovetails means even if adhesive degrades over time, the joint geometry continues providing structural support. For contractors, dovetails reduce callback risk and serve as a visible quality indicator clients recognize—when they open a drawer and see dovetail craftsmanship, it reinforces their investment in premium cabinetry. The cost differential versus dowel construction typically runs 15-25%, but the longevity and perceived value far exceed this premium.

Can I use pocket screws for professional cabinet construction?

A: Yes, when used strategically and correctly. Pocket screws excel for face frame assembly, cabinet stretchers, and applications where holes can be concealed on interior surfaces. The critical requirements: always combine pocket screws with wood glue (screws provide clamping pressure while glue creates permanent bonds), use correct screw length for material thickness (1-1/4″ screws for 3/4″ stock), and space holes appropriately (6-8″ intervals with minimum two per joint). Where pocket screws fall short: primary structural joints under tension, visible surfaces requiring plugs, and applications where traditional joinery better serves the aesthetic (door frames should use mortise-and-tenon rather than pocket screws). Many professional cabinet makers use pocket screws extensively for face frames—positioned on the backside where invisible—achieving tight, flush joints faster than traditional methods while maintaining commercial-grade strength when properly glued.

Fabuwood-Specific Questions

What makes Fabuwood’s joinery different from other cabinet manufacturers?

Fabuwood’s Q12 Quality System standardizes construction methods typically offered as premium upgrades by competitors.

Key differentiators include:

(1) Dovetail drawer construction standard across all price points rather than reserved for luxury lines;

(2) Full 1/2″ solid plywood backs (one-piece, not stapled sections) providing superior racking resistance;

(3) Threespine® Click Technology in frameless Illume series creating tool-less assembly with mechanical interlocks;

(4) All-plywood box construction—sides, tops, bottoms—eliminating particle board common in competing mid-range products;

(5) Blum hardware integration throughout (not mixed-quality components), and

(6) KCMA certification validating 25,000-cycle durability claims through independent testing.

Industry analysis shows Fabuwood delivers AWI Custom Grade specifications at approximately 30% below comparable semi-custom brands when competitors’ plywood upgrades are factored. For contractors, this means specifying premium construction without premium pricing.

How does Fabuwood’s Q12 system compare to KCMA certification?

Q12 represents Fabuwood’s internal quality standards while KCMA provides independent third-party validation—they complement rather than compete. Q12 establishes specific construction specifications (dovetail joints, 1/2″ backs, Blum hardware, etc.) that define what Fabuwood builds into every cabinet. KCMA certification validates that these constructions perform under standardized testing: 25,000 door/drawer cycles, 600-pound wall cabinet loading, chemical resistance, and impact durability.

Think of Q12 as the manufacturing blueprint and KCMA as the independent audit confirming performance. Contractors benefit from both: Q12 specifications provide talking points for client discussions (explaining visible quality features), while KCMA certification offers documented proof that construction methods deliver measurable durability. When specifying cabinets, look for manufacturers offering both proprietary quality systems AND third-party validation—this combination indicates construction claims backed by verifiable testing rather than marketing assertions.

Does IST Cabinets offer contractor pricing on Fabuwood products?

Yes—IST Cabinets provides specialized contractor pricing, dealer programs, and professional loyalty benefits for qualified trade professionals. The Professional Loyalty Program includes volume-based pricing tiers, priority order processing, dedicated technical support, and access to Fabuwood’s complete product line including Allure (face frame) and Illume (frameless) series. Additional benefits include project planning assistance, specification writing support, and expedited delivery for time-sensitive installations. Contractors serving Virginia and the Mid-Atlantic region particularly benefit from IST Cabinets’ regional inventory positioning, reducing lead times compared to national distributors. To qualify, professionals typically need to provide contractor license verification, business insurance documentation, and complete a brief application. Learn more about professional membership benefits and pricing tiers at istcabinets.com.

Technical Specification Questions

What thickness plywood should I specify for quality cabinets?

Follow AWI specifications aligned with project grade: Custom Grade (standard residential): 1/2″ sides minimum, 1/2″ backs, 3/4″ shelves and bottoms; Premium Grade (high-end residential/commercial): 3/4″ sides, 3/4″ backs, 3/4″ shelves and bottoms. Economy cabinets using 1/4″ backs and 1/2″ sides with particleboard represent substandard construction unsuitable for professional installations. Fabuwood exceeds Custom Grade baseline with 1/2″ sides and full 1/2″ one-piece backs (not stapled sections) as standard, with 3/4″ upgrades available. The performance difference is measurable: testing shows 1/2″ backs reduce racking (twisting) by approximately 40% versus 1/4″ alternatives, while 3/4″ sides improve screw-holding by 60% compared to 1/2″ material. For drawer boxes, specify 1/2″ minimum sides (5/8″ optimal) with 1/4″ to 3/8″ bottoms captured in dados rather than stapled. All plywood should meet CARB Phase 2 formaldehyde emissions standards.

How do I evaluate cabinet joinery during a job site inspection?

Use this systematic approach:

(1) Drawer Inspection: Pull drawers completely—examine corner joints for dovetails (premium), dowels (acceptable), or staples (economy). Check bottom panel attachment: dadoed grooves indicate quality, stapled bottoms suggest cost-cutting. Test slides for smooth full-extension and soft-close operation.

(2) Door Frame Check: Open doors fully and examine frame corners where rails meet stiles. Tight, seamless joints indicate mortise-and-tenon or quality dowel construction; visible gaps or misalignment suggest inferior joinery. Feel corner edges—they should be flush without height differences.

(3) Cabinet Box Assessment: Look inside cabinets for back panel thickness (1/2″ minimum for quality), corner reinforcement (braces, blocks, or interlocking joints versus simple butt joints), and shelf support method (dado grooves better than plastic clips alone).

(4) Hardware Evaluation: Test hinges for smooth, quiet closing with integrated soft-close—cheap hinges slam or create noise. Check for brand markings (Blum indicates quality hardware).

(5) Material Verification: Examine cut edges to distinguish plywood (layered construction) from particle board (compressed chips). Quality cabinets use plywood for structural components.

What’s the difference between face frame and frameless construction quality?

Neither construction style is inherently superior—both can achieve excellent quality with proper execution, though they suit different applications.

Face frame construction (American traditional) adds structural rigidity through the front frame, simplifies installation with easier shimming, and provides traditional aesthetics. Quality face frame cabinets feature 3/4″ thick solid wood frames (1-1/2″ wide minimum) attached with dowels and glue to plywood boxes. The frame-to-box joint quality matters significantly—premium construction uses multiple dowels or biscuits with glue clamping, while economy approaches may use only staples or minimal fasteners.

Frameless construction (European/32mm system) maximizes interior space (approximately 1″ more depth), enables wider drawers, and delivers contemporary aesthetics. Quality depends on box construction strength since no front frame provides reinforcement—require 1/2″ minimum sides (3/4″ optimal), full backs, and corner interlocking or substantial bracing. Fabuwood’s Illume frameless series uses Threespine® Click Technology creating rigid mechanical joints without fasteners. For contractors: face frame suits traditional designs and forgiving installation conditions; frameless offers modern aesthetics and space efficiency but demands precision installation and robust box construction.

Installation & Hardware Questions

Why does Blum hardware cost more than alternatives?

A: Blum’s premium pricing reflects measurable performance advantages and long-term value:

(1) Durability Testing: Blum CLIP top hinges test to 200,000 cycles versus 50,000-100,000 for economy alternatives; TANDEM slides test to 100,000 cycles at 90-150 lb capacity while basic slides often fail under 75 pounds after 25,000 cycles.

(2) Integrated Soft-Close: Blum BLUMOTION self-adjusts to door/drawer weight and closing force, requiring no adjustment—cheap add-on soft-close mechanisms require calibration and often fail early.

(3) Tool-Free Adjustment: CLIP technology enables hinge mounting without screwdrivers; six-way adjustment compensates for out-of-plumb walls without replacement. Economy hinges typically offer limited adjustment requiring complete remounting.

(4) Warranty & Support: Blum offers extensive technical documentation, replacement parts availability, and responsive contractor support.

(5) Client Perception: Homeowners increasingly recognize Blum branding as quality indicator—just as they know premium appliance brands. For contractors, the 20-30% price premium over generic hardware translates to fewer callbacks, easier installation, and enhanced perceived project value. Calculate total cost including installation time and callback risk—Blum often proves economical long-term.

How do I properly adjust cabinet doors with Blum hinges?

Blum CLIP top hinges offer three-dimensional adjustment addressing common door issues:

(1) Height Adjustment (Vertical): Loosen mounting plate screws (2-3 on cabinet interior), shift door up or down, retighten. Typical range: ±2-3mm. Use for aligning door tops/bottoms with adjacent doors or drawer fronts.

(2) Lateral Adjustment (Side-to-Side): Use screws on hinge arm (visible when door open) to shift door left or right. Typical range: ±2-3mm. Use for centering doors in cabinet opening or adjusting reveals between adjacent doors.

(3) Depth Adjustment (In-and-Out): Turn adjustment screw at back of hinge arm (near door) to move door toward or away from cabinet face. Typical range: -2mm to +4mm. Use for flush alignment with face frame or adjacent cabinet doors.

Pro tip: Make incremental 1/8-turn adjustments and test operation—overcorrection requires reversal. For doors spanning multiple hinges, adjust all hinges equally to prevent binding. If adjustments reach maximum range without achieving proper fit, verify cabinet installation is plumb and level—hinge adjustment compensates for minor irregularities but cannot correct major installation issues.

Q: What drawer slide specifications should I require for quality installations?

A: Specify these minimum standards for professional installations:

(1) Load Capacity: 90-100 lbs for standard drawers, 100-150 lbs for heavy-use applications (pots/pans, dishes). Economy slides rated below 75 lbs are unsuitable for kitchen cabinets.

(2) Extension: Full-extension capability (drawer box extends completely beyond cabinet face) is now expected standard—3/4 extension slides indicate economy construction.

(3) Soft-Close Integration: Integrated soft-close mechanisms (like Blum BLUMOTION) self-adjust and require no maintenance—prefer these over add-on dampers requiring periodic adjustment.

(4) Mounting Style: Undermount slides (attached to drawer bottom) provide clean appearance and maximize drawer interior width; side-mount slides consume interior space but cost less.

(5) Cycle Rating: Minimum 50,000 cycles; 100,000+ cycles for premium installations.

(6) Installation Tolerance: Quality slides tolerate slight misalignment (±1mm); cheap alternatives bind if not perfectly positioned.

(7) Brand Verification: Blum TANDEM, Salice, Grass, Hettich represent quality manufacturers with documented specifications—generic unbranded slides lack verifiable performance data. For contractors, undermount full-extension soft-close slides rated 100 lbs with 100,000-cycle durability represent the current professional baseline—anything less positions the project as economy-grade.

Joinery Methods: When to Specify Each Type

| Application | First Choice | Alternative | Avoid |

|---|---|---|---|

| Door Frame Corners | Mortise & Tenon | Dowels (3+ per joint) | Pocket screws, staples |

| Drawer Box Corners | Dovetail | Dowels (quality glue) | Staples, butt joints |

| Face Frame Assembly | Dowels or Pocket Screws + Glue | Mortise & Tenon | Staples alone |

| Cabinet Box Shelves | Dado + Rabbet | Dado alone | Butt joints with brackets |

| Cabinet Box Corners | Dado + Corner Blocks | Rabbet joints | Simple butt joints |

| Mid-Panel Connections | Floating Tenon (Domino) | Dowels | Pocket screws |

Conclusion: Building Lasting Value Through Superior Joinery

Mastering joinery techniques in Shaker cabinet construction requires understanding the interconnection between traditional craftsmanship principles, modern manufacturing technology, and industry certification standards. The specifications detailed throughout this guide—from Fabuwood’s Q12 system requiring dovetail construction and 1/2″ solid plywood backs to KCMA’s 25,000-cycle durability testing and AWI’s three-grade specification hierarchy—provide the technical foundation for informed evaluation and specification.

The key insight for contractors and dealers: quality claims become verifiable through certification compliance, material specifications, and hardware selection. Blum hardware rated for 200,000 cycles, KCMA-certified structural testing, and AWI-compliant joinery methods translate manufacturer marketing into measurable standards. When discussing cabinet quality with clients, these specifications provide authoritative responses that build trust and demonstrate expertise.

For professionals serving the Virginia and Mid-Atlantic region, understanding these construction fundamentals enables confident recommendations that match client budgets with appropriate quality levels—from Custom Grade specifications suitable for most residential projects to Premium Grade requirements for high-end applications demanding the finest materials and craftsmanship.

Partner With IST Cabinets for Your Next Project

IST Cabinets proudly serves contractors, dealers, and builders throughout Virginia and the Mid-Atlantic region with:

🏆 Exclusive Fabuwood Partnership: Complete access to Q12-certified Allure and Illume series with full technical support

💰 Professional Loyalty Program: Volume-based pricing, priority order processing, and dedicated account management

📐 Technical Assistance: Specification writing support, material selection guidance, and installation consultation

⚡ Regional Advantage: Local inventory positioning for faster delivery and reduced lead times

🛠️ Trade-Focused Service: We understand contractor timelines, job site requirements, and builder expectations

Ready to elevate your next cabinetry project?

- Explore Fabuwood’s Q12-Certified Collection → View Products

- Join Our Professional Loyalty Program → Learn More

- Request Project Quote & Specifications → Contact Us

- Download Free Pricing Guide → Get Catalog

IST Cabinets | Professional Cabinetry Solutions Serving Virginia & the Mid-Atlantic Region 📞 Contact Us Today | 🌐 istcabinets.com

Quality joinery isn’t just about construction—it’s about delivering projects that enhance your reputation and keep clients satisfied for decades. Let’s build something exceptional together.